Manufacturing execution systems (MES) in an era of skilled labor challenges

The Fabricator

MARCH 24, 2023

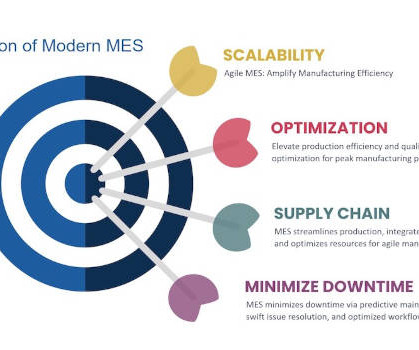

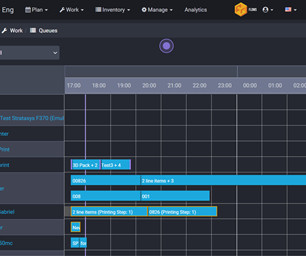

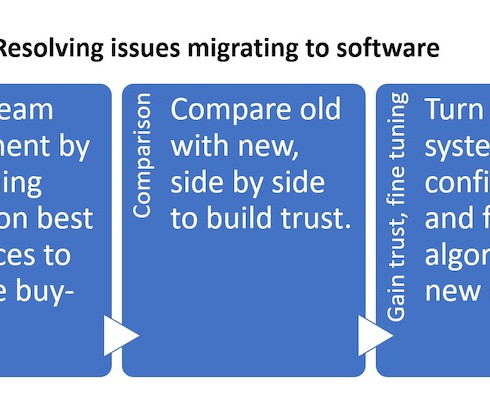

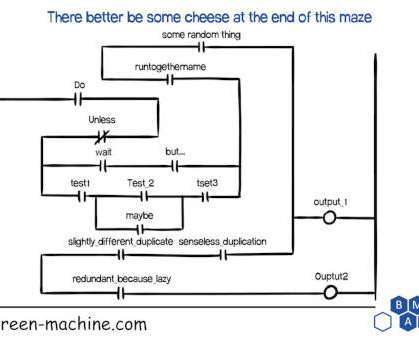

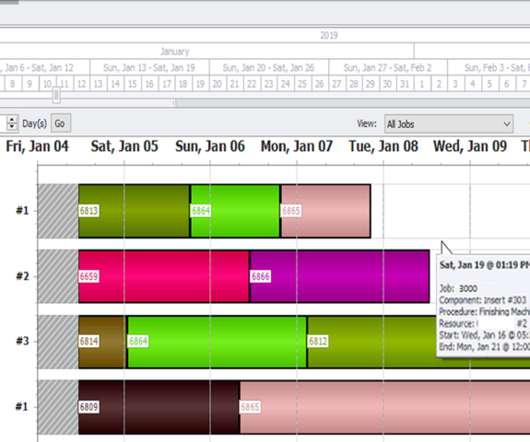

Here, manufacturing execution systems (MES) can help. Fabricators know all about automating laser cutting, bending, welding, and powder coating, but what about automating and streamlining the flow of information?

Let's personalize your content