Scaling OEE to Digitize Lean Manufacturing

Automation World

MAY 30, 2024

Bayer Crop Science shares how it uses Siemens’ Opcenter Intelligence and Insights Hub software to digitally transform its operations around an OEE center point

This site uses cookies to improve your experience. By viewing our content, you are accepting the use of cookies. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country we will assume you are from the United States. View our privacy policy and terms of use.

Lean manufacturing Related Topics

Lean manufacturing Related Topics

Automation World

MAY 30, 2024

Bayer Crop Science shares how it uses Siemens’ Opcenter Intelligence and Insights Hub software to digitally transform its operations around an OEE center point

Gary Mintchell

APRIL 18, 2023

Well, many organizations including this one are working to restore America’s manufacturing prowess. Making Lean Manufacturing more widespread is a good start. Industry Reimagined 2030 just released its research report “ The State of Lean Manufacturing.” Sentiment analysis was performed.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

MRPEasy

FEBRUARY 28, 2023

The lean manufacturing methodology chiefly revolves around minimizing production times and raising efficiency by eliminating waste. In this post, we go through the 8 principal wastes in lean manufacturing and see how manufacturing software can help to address them. What is waste in lean manufacturing?

The Fabricator

DECEMBER 1, 2022

Is your metal fabrication shop sustaining your lean manufacturing journey, or are you letting things backslide? It’s time for reflection.

The Fabricator

AUGUST 1, 2022

Those that resist lean manufacturing efforts need to see the negative impact nonvalue-added activities can have on metal fabrication shops and other facilities.

The Fabricator

AUGUST 29, 2022

Has your metal fabrication shop's lean manufacturing journey stalled or faltered? If so, it’s time for a relaunch.

Factory Worx

SEPTEMBER 23, 2022

The post What is Lean Manufacturing and its Six Core Principles? appeared first on Factoryworx.

Canadian Manufacturing

AUGUST 16, 2023

Flexpipe announces the launch of its Lean Maker Academy to support lean manufacturing QUEBEC CITY — On Aug. Flexpipe announces the launch of its Lean Maker Academy to support lean manufacturing QUEBEC CITY — On Aug. Train as many people as you want on a schedule that meets their needs and yours.”

ATS

OCTOBER 24, 2022

In the ongoing pursuit of increased efficiency and improved profit margins, lean manufacturing is one of the most impactful practices that organizations have adopted over the past several decades – and its influence remains significant to this day. What is lean manufacturing?

Nexus Integra

MAY 31, 2022

Also known as “lean production”, this work philosophy is essential for any company that is part of Industry 4.0. What is Lean Manufacturing? Lean Manufacturing stands out. Lean Manufacturing is a philosophy whose main function is to eliminate everything that does not add value in a production process.

The Fabricator

NOVEMBER 5, 2022

Do you focus on lean tools but ignore the philosophy? Or do you opine about lean philosophy but ignore the tools? Doing either can kill an improvement initiative.

Mold Making Technology

JANUARY 23, 2023

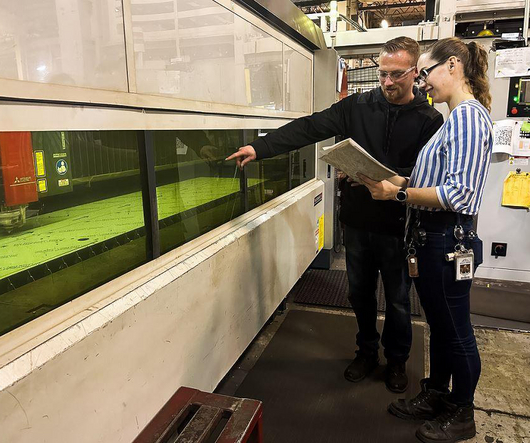

From manufacturing and project engineering to lean manufacturing, Six Sigma and sustainability, Katherine Pistorius has turned her passions into a fulfilling career in manufacturing. I work on a portfolio of short- and long-term projects simultaneously on top of workshops, and team trainings.

The Fabricator

DECEMBER 29, 2022

After seven years of writing for The FABRICATOR, columnist Jeff Sipes writes his send-off by addressing the past, future, and the fundamentals at lean manufacturing’s core.

Design World

JANUARY 8, 2023

The top goal of most digital transformation (DX) initiatives sounds suspiciously similar to that of lean-manufacturing methodologies — to minimize an operation’s waste and cost while concurrently maximizing its quality (defect-free) throughput of customer-coveted product.

The Fabricator

JUNE 10, 2024

Lean Manufacturing Products offers the Re-Rack cartridge, designed to secure sheet metal to streamline the transportation of materials between suppliers and vendors.

The Fabricator

JANUARY 24, 2023

Longtime industry consultant Gary Conner recalls his days implementing lean manufacturing concepts and eliminating waste in the sheet metal job shop.

Fabricating & Metal Work

JULY 18, 2024

High-density storage systems from LEAN Manufacturing Products. The LEAN Re-rack cartridge is crafted to streamline the transportation of sheet metal between suppliers and vendors.

The Fabricator

APRIL 11, 2024

Formed in 2023, SOLV Metals represents the merger of three industry players: Wisconsin Metal Parts, Lean Manufacturing Products, and QuikCut. The story reveals the subtle nature of consolidation in metal fabrication.

The Fabricator

OCTOBER 1, 2022

Are you serious about lean manufacturing, or are you just dabbling? Considering the state of the world, now would be a good time to get serious.

The Fabricator

FEBRUARY 20, 2023

Conventional wisdom in lean manufacturing says that material handlers should stage tools and material for operators. The less wasted movement operators make, the better. Still, how does this affect shop culture and idea generation? It's worth putting more value in talking a communication in the metal fabrication job shop.

MRPEasy

JANUARY 17, 2024

Takt time is a key concept in lean manufacturing and process management, representing the rate at which a finished product needs to be completed in order to meet customer demand. Takt time is a key concept in lean manufacturing […] The post What Is Takt Time and How to Use It? What is takt time?

The Fabricator

FEBRUARY 1, 2024

based Hennig is a strict adherent to lean manufacturing practices as it tries to increase generator enclosure production. Machesney Park, Ill.-based

The Fabricator

AUGUST 25, 2022

A decade ago, a speaker at an FMA lean manufacturing conference revealed a proposed shop layout to promote flow. The bones behind the concept still apply to the industry today.

Robotics Automation News

MAY 13, 2024

Institutions like Kettering University Online are responding to this need by offering specialized online Masters in automotive engineering programs and lean manufacturing, which is aimed at preparing students for careers where technology […]

The Fabricator

FEBRUARY 10, 2024

For many fabricators, the classic wastes of lean manufacturing are mere symptoms of an underlying disease: an inefficient shop layout.

MRPEasy

MARCH 22, 2024

Process improvement in manufacturing is not just about tweaking a few procedures. It involves a holistic approach, integrating time-tested methodologies such as lean manufacturing, Six Sigma, and Kaizen, with cutting-edge solutions like manufacturing ERP software. What is process improvement?

The Fabricator

AUGUST 10, 2023

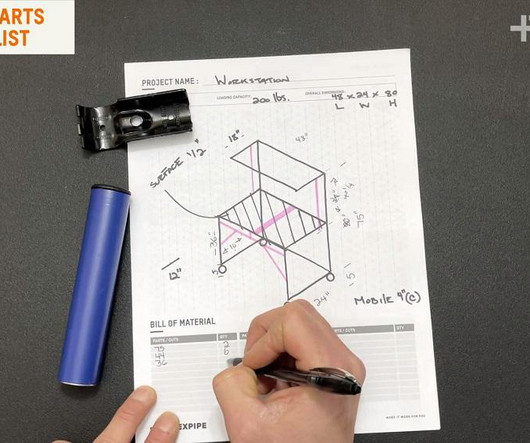

Flexpipe as launched its free Lean Maker Academy, an online certification program designed to teach workers to assemble modular system equipment for lean manufacturing.

NIST

JANUARY 5, 2023

There is more to lean manufacturing than improving a few processes. Sustainable lean success requires a companywide culture of continuous daily improvement. Companies that develop their people to think scientifically, using facts and data to drive their decisions, are often the ones that most successfully achieve their goals.

The Fabricator

JANUARY 29, 2024

Metal manufacturer and fabricator Solv Metals LLC, a division of Solv Holdings, Fort Wayne, Ind., has announced the acquisition of Wisconsin Metal Parts (WMP) and Lean Manufacturing Products, both in Waukesha, Wis.

Manufacturer's Monthly

MAY 1, 2024

Whether you specialise in lean manufacturing workshops, advanced automation courses, environmental compliance seminars, or leadership training, Manufacturers’ Monthly is the perfect platform to showcase your services. This is where you come in.

NIST

AUGUST 23, 2022

All too often, PCL is missing from lean manufacturing, causing many In PCL, leadership focuses on providing employees with what they need to go home feeling like they are flourishing and helping to fulfill a greater common purpose, which is important for morale and retention, innovation and product quality.

Manufacturing Tomorrow

AUGUST 24, 2023

Flexpipe's Free Lean Maker Academy is the First Online Certification Program to Teach Workers How to Assemble Modular System Equipment for Lean Manufacturing

Manufacturing Tomorrow

SEPTEMBER 20, 2022

The largest lean manufacturing conference in the world will meet in person to share best practices for the first time since 2019

WMEP

JANUARY 13, 2023

January 5, 2023By: Sarah Burlingame There is more to lean manufacturing than improving a few processes. Sustainable lean success requires a companywide culture of continuous daily improvement.

NIST

AUGUST 23, 2022

All too often, PCL is missing from lean manufacturing, causing many In PCL, leadership focuses on providing employees with what they need to go home feeling like they are flourishing and helping to fulfill a greater common purpose, which is important for morale and retention, innovation and product quality.

Modern Machine Shop

JANUARY 2, 2024

“Our Ignition projects have demonstrated the immense potential for data-driven, lean manufacturing and operational excellence, and has inspired us to integrate Ignition programming as a cornerstone of our 2024 initiative,” Craig Salvalaggio, company president, says.

Manufacturing Management

FEBRUARY 1, 2023

The Manufacturing Institute (TMI) has received City & Guilds assurance for the Team Leadership Development Programme (TLDP) and the Accelerated Route to Lean Manufacturing (ARTL). These are often the gateway onto the MSc in Manufacturing Leadership, or even larger continuous improvement consultancy projects and Shingo.

Manufacturing & Logistics IT

SEPTEMBER 8, 2016

Global manufacturing supply chains face regular challenges: rising material and energy costs, smaller, local competitors offering lower prices and, studies now show, $900 billion lost in waste. In order to survive, manufacturers need to shift their mind-set, adapting existing processes to work with greater efficiency and precision.

Manufacturing Tomorrow

JUNE 28, 2023

Half Day Workshop to be offered on Lean Manufacturing – The Culture of Kaizen

i4.0 today

JUNE 14, 2024

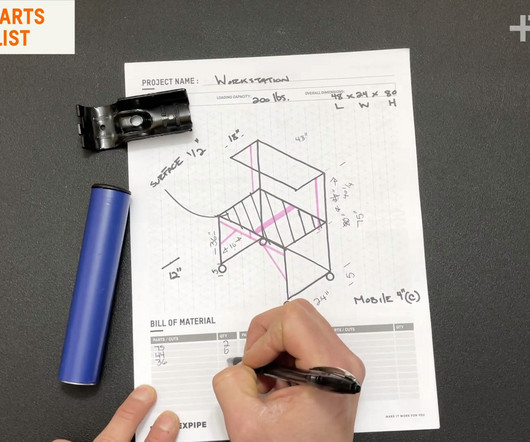

The workstations offer a highly configurable, compact unit designed for lean manufacturing. Two standout products from AMADA’s Laser Marking lineup are the Laser Marking Workstation (WL-100A) and the Fiber Laser Marker (LM-F100A). Offering a broad range of marking capabilities for various metals, plastics, and ceramics.

NIST

JANUARY 14, 2022

The lean manufacturing movement came out of a desire to reduce waste and inefficiencies and improve productivity in the operation. Many manufacturers have also benefited from the resulting continuous improvement mindset as engaged employees became empowered to change things for the better.

Manufacturer's Monthly

FEBRUARY 15, 2024

When it comes to making workstations safe, comfortable, and efficient, ergonomics and lean manufacturing go hand in hand. The HOOB team excels in integrating ergonomics in lean manufacturing, improving both employee performance and satisfaction.

AU Manufacturing

MAY 4, 2023

The initiative is encouraging and supporting people in sectors such as metal, engineering and boating; a erospace; process manufacturing, including chemicals, hydrocarbons, mineral products, plastics and rubber; and recreational vehicles.

Modern Machine Shop

JULY 20, 2023

During his career, Frank studied and trained in lean manufacturing, value stream mapping, ISO processes/audits, OSHA compliance, cost reduction, facility/line set-up and operator training. Twomey’s first job after graduating from Piedmont Technical Institute in 1991 was as a machinist at Ross Industries.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content