The New Cybersecurity Trending Dashboard (Beta)

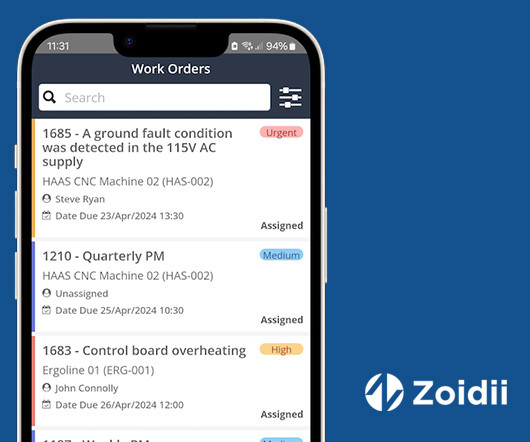

Canadian Metalworking Magazine

SEPTEMBER 17, 2020

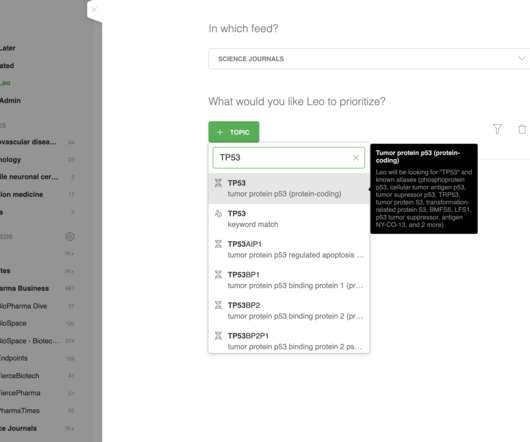

An at-a-glance overview of the evolving cybersecurity threat landscape. Keeping up with the most critical threats, vulnerabilities, and threat actors can be time consuming and overwhelming. We have been working with a few existing Feedly for Cybersecurity customers to create a trending dashboard that offers an at-a-glance overview of the evolving cybersecurity threat landscape.

Let's personalize your content