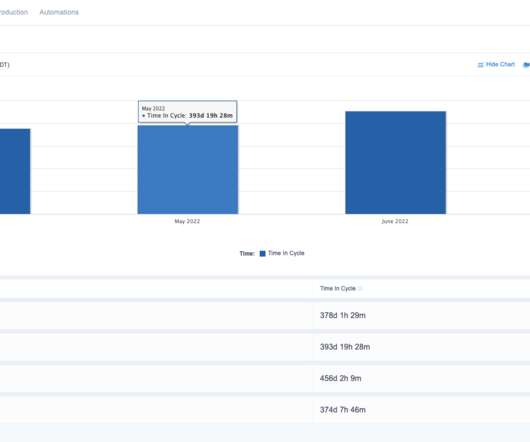

How Cycle Time Reduction Improves Operational Efficiency

Granta Automation

JULY 10, 2024

One of the most effective ways to enhance operational efficiency is through cycle time reduction. Cycle time refers to the total duration taken to complete a process from start to finish.

Let's personalize your content