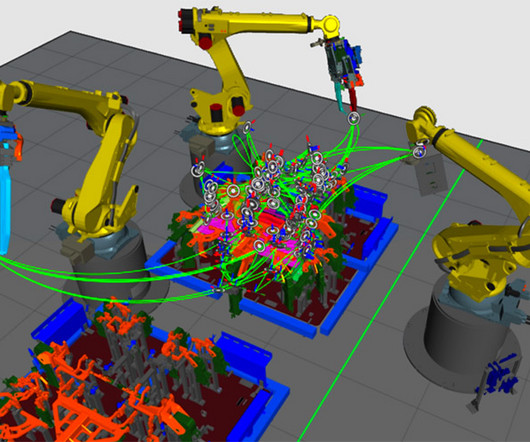

Valiant TMS and Realtime Robotics partner to cut programming, cycle times

Robotics Business Review

JANUARY 8, 2024

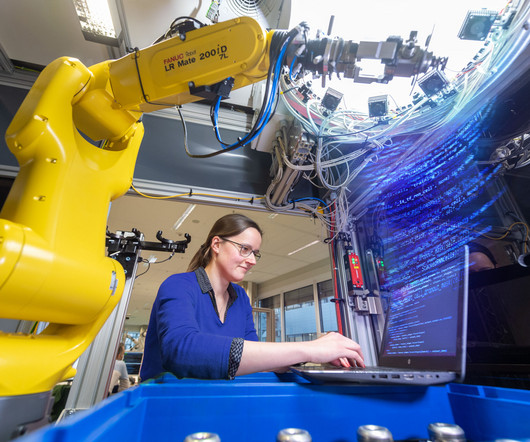

The companies said the combination of Realtime’s proprietary software and engineering expertise with Valiant TMS’s manufacturing industry experience will improve the efficiency and productivity of automated operations. It ultimately reduced a customer’s robot cycle time by 17% and cut robot programming time in half. “I

Let's personalize your content