Advancing motion control applications with the right drives, technology

Control Engineering

AUGUST 3, 2023

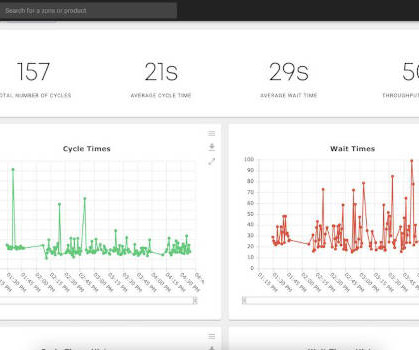

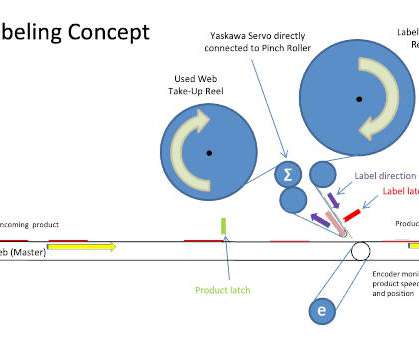

Driving advanced data sharing for demanding manufacturing cycle times To accommodate increasingly demanding cycle times while offering exacting performance and maximum uptime, engineers should look for drives and controls that use a network technology that ensures determinism.

Let's personalize your content