Humanoid robots promise a multi-trillion-dollar market, but pose challenges

Robotics Business Review

FEBRUARY 23, 2025

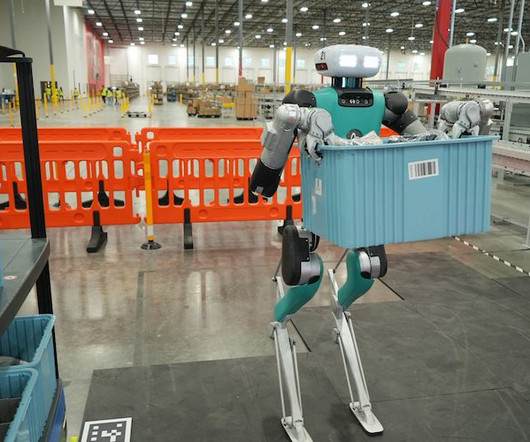

Agility Robotics’ Digit humanoid was in trials at GXO. Source: Agility Robotics As an early investor in Agility Robotics, now one of the world’s leading manufacturers of humanoid robots, I’ve watched as humanoids have evolved from a fascinating concept to reality over the past five years.

Let's personalize your content