The Shift Toward Smarter Shops: Real-World Stories of Data-Driven Manufacturing

Modern Machine Shop

APRIL 29, 2025

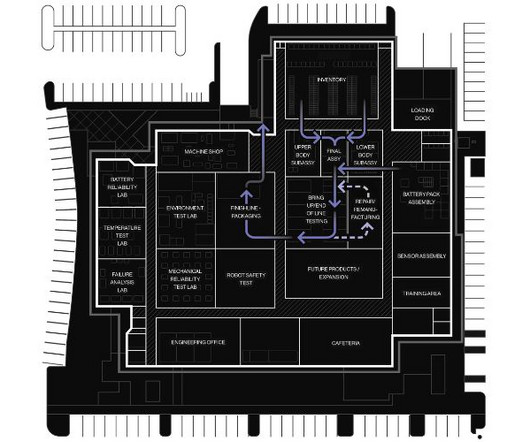

When these slow-moving robots are activated in the coming months, they will serve as active transport systems, using optical navigation and laser scanning technologies to guide DMG MORI’s universal turning centers through different stages of the assembly process. Robots and cobots are nearly ubiquitous.

Let's personalize your content