Valiant TMS and Realtime Robotics partner to cut programming, cycle times

Robotics Business Review

JANUARY 8, 2024

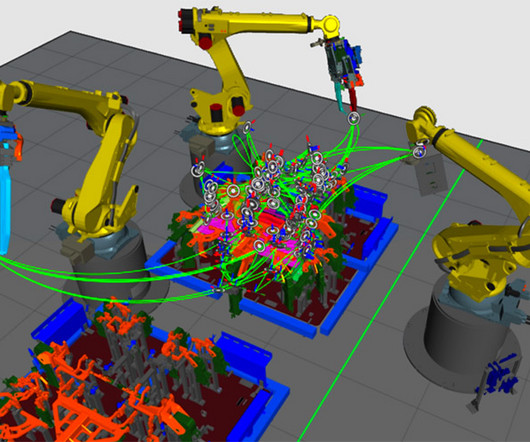

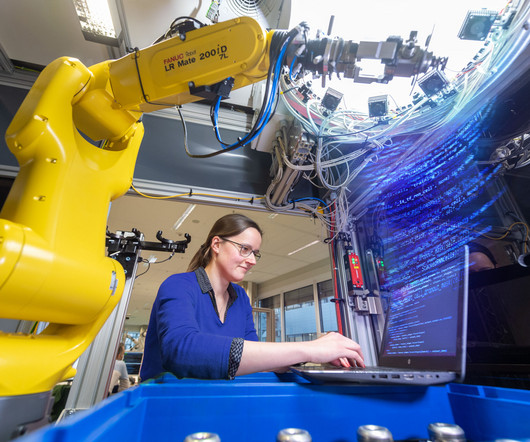

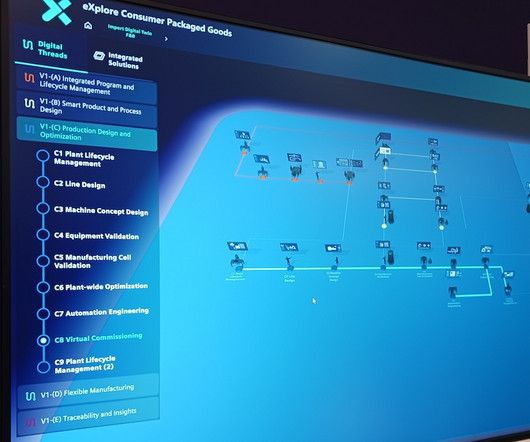

Source: Realtime Robotics Realtime Robotics today announced that Valiant TMS will integrate its Optimization-as-a-Service offering with customers’ manufacturing operations. Boston-based Realtime Robotics claimed to be a leading provider of automatic, collision-free motion planning for industrial robots.

Let's personalize your content