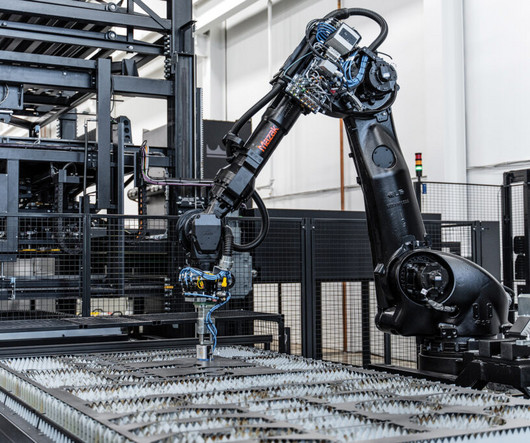

Automation in action: Robotic cleaning is the future

Manufacturer's Monthly

MAY 11, 2025

Images: Tennant As automation reshapes production lines, its also transforming how facilities are maintained. Robotic cleaning is no longer a futuristic concept, its todays best solution for tackling the rigorous demands of industrial environments. Why robotic cleaning? Built on experience. powered by innovation.

Let's personalize your content