Manufacturing KPIs

eFlex Systems

JANUARY 11, 2024

There are three essential prerequisites for setting and measuring manufacturing KPIs – a consistent process, clear standards, and the tools to measure. Read on in the Epicor blog.

This site uses cookies to improve your experience. To help us insure we adhere to various privacy regulations, please select your country/region of residence. If you do not select a country, we will assume you are from the United States. Select your Cookie Settings or view our Privacy Policy and Terms of Use.

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

Used for the proper function of the website

Used for monitoring website traffic and interactions

Cookies and similar technologies are used on this website for proper function of the website, for tracking performance analytics and for marketing purposes. We and some of our third-party providers may use cookie data for various purposes. Please review the cookie settings below and choose your preference.

manufacturing-kpis

manufacturing-kpis  Blog Related Topics

Blog Related Topics

eFlex Systems

JANUARY 11, 2024

There are three essential prerequisites for setting and measuring manufacturing KPIs – a consistent process, clear standards, and the tools to measure. Read on in the Epicor blog.

MRPEasy

JULY 1, 2024

In this guide, we outline the top 11 supply chain KPIs to help you focus on critical areas of your supply chain performance. What are supply chain KPIs?

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

MRPEasy

DECEMBER 26, 2022

The goal of every manufacturing business is to be as efficient as possible. Here is where manufacturing KPIs come into play. But without being able to accurately gauge your efficiency, it is hard to know where you stand and what goals to set.

MRPEasy

MAY 23, 2023

Tracking inventory management KPIs can go a long way in achieving these goals. In this post, we look at 11 of the most important inventory management KPIs and give tips on how to put them to use.

ATS

JANUARY 8, 2025

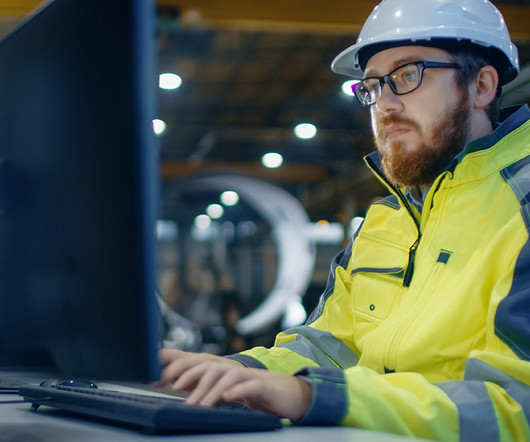

Whiteboards, cards and spreadsheets may have had their place, but manufacturers who are serious about improving their competitive position should look to one tool, a computerized maintenance management system (CMMS). This blog takes a close look at CMMS software. A good solution for small to medium-size manufacturers.

CMTC Manufacturing Tech

JANUARY 16, 2025

As covered in our previous blog , warehousing and distribution management is of critical importance. When its pumping reliably, your manufacturing operations benefit from predictability providing your business with a rock-solid foundation for growth. Your warehouse is like the beating heart of your supply chain.

MRPEasy

NOVEMBER 24, 2022

The many cost-oriented KPIs in manufacturing accounting constitute some of the most important financial metrics for manufacturers and distributors. In this post, we look at the function and relevance of one such KPI – the Cost of Goods Sold. What is the Cost of Goods Sold? The Cost of Goods Sold, or COGS is a […].

ATS

FEBRUARY 12, 2025

Share Lean manufacturing focuses on eliminating waste and optimizing processes to achieve maximum efficiency and expediency. This is why conducting a bottleneck analysis in lean manufacturing operations is such a critical step for manufacturers to take. What is bottleneck analysis?

MRPEasy

APRIL 17, 2023

Using SKU codes for inventory tracking allows you to avoid stockouts and overstocking, ensure effective picking and dispatch, and track inventory performance related KPIs. appeared first on Blog for Manufacturers and Distributors. What is a Stock Keeping Unit (SKU)?

ATS

MARCH 25, 2025

While the primary goal in maintenance strategy is to keep machines running, it also impacts larger corporate objectives such as lean manufacturing initiatives or overall equipment effectiveness (OEE). Sharing these KPIs with production and operations helps improve synergy. This starts with strategic alignment.

ATS

FEBRUARY 12, 2025

This is why many manufacturers and production facilities have a dedicated maintenance supervisor on staff to oversee these mission-critical tasks. Communication and reporting: Supervisors must be able to keep management updated on maintenance KPIs such as downtime and repair costs.

ATS

OCTOBER 2, 2024

This blog is about ways of measuring maintenance performance. After clarifying the relationship between KPIs and metrics, it reviews the four categories, discusses which are most important and offers some guidance on using them. What are industrial maintenance KPIs? In manufacturing, KPIs often relate to output.

ATS

MAY 14, 2025

Share Uneven customer demand creates significant challenges for manufacturers: increased overtime, excess inventory, and wasted labor, among other obstacles. Instead, production leveling or Heijunka offers a proactive solution rooted in Lean manufacturing. Launch a pilot line , gather real-time data, and iterate.

CMTC Manufacturing Tech

JANUARY 25, 2024

In this blog, we’ll explore the key elements of a long-term strategic plan to help you navigate today’s competitive manufacturing landscape. For instance, a very small manufacturer will never be able to match the production volume capabilities of a larger competitor. There are countless KPIs that SMMs can measure.

MRPEasy

JANUARY 20, 2024

Tracking inventory management KPIs can go a long way in achieving these goals. In this post, we look at 11 of the most important inventory management KPIs and give tips on how to put them to use.

MRPEasy

NOVEMBER 27, 2023

Cycle time is the time it takes to complete a single manufacturing operation. It is a manufacturing KPI used to measure the efficiency of specific production processes and to discover and eliminate bottlenecks. appeared first on Blog for Manufacturers and Distributors. What is cycle time?

ATS

SEPTEMBER 5, 2023

Manufacturing production reports are one of the key facilitators of this decision-making. Production reporting provides real-time insights into the processes and metrics that matter most to the organization — those that have been identified as key performance indicators (KPIs). What is production reporting?

ATS

FEBRUARY 14, 2024

This blog explains what enterprise asset management entails, the benefits it delivers and how it relates to computerized maintenance management systems (CMMS). If you’re looking for ways to reduce CapEx and OpEx, this blog will provide some ideas to follow up on. EAM software helps manufacturers pursue these objectives.

CMTC Manufacturing Tech

JANUARY 25, 2023

Lean manufacturing is much more than a collection of tools. In this blog, we address why culture matters. Lean helps manufacturers focus on what customers expect by identifying what products, features, processes, and activities are of value to customers and seeks to remove or minimize everything else. Why Become Lean?

ATS

OCTOBER 8, 2024

Share Industrial chillers are key elements of many manufacturers’ operations, removing heat from fluids for air conditioning, dehumidification and controlled cooling for various applications. Having a chiller maintenance checklist is one important step all manufacturers should take, but there’s more to it than simply getting organized.

ATS

OCTOBER 24, 2022

Maintenance in manufacturing is a many-faceted undertaking, comprising an extensive toolset of tactics and practices. The Alpha Strike rapid improvement event is built on the Kaizen event foundation, drawing from continuous improvement and Kaizen lean manufacturing principles to drive analysis, action and results.

ATS

OCTOBER 2, 2024

Businesses that reduce waste in manufacturing increase their margins and shrink their environmental impact. What is predictive maintenance, and how does it help with reducing waste in manufacturing? Reducing material waste with predictive maintenance Predictive maintenance helps reduce material waste in manufacturing.

ATS

JUNE 12, 2024

Key areas of focus in a maintenance audit In the typical manufacturing business, the maintenance function works with many other teams. Key performance indicators (KPIs): Maintenance effectiveness can only be improved if appropriate metrics are in place. Elsewhere, use KPIs taken from the CMMS. Contact us to learn more.

CMTC Manufacturing Tech

MARCH 20, 2024

Small and medium-sized manufacturers with successful supply chains rely heavily on robust production planning. Optimizing the production plan, which takes into account the manufacturing process from raw materials to finished goods, can enhance a company’s operational efficiency, cost savings, and customer satisfaction.

ATS

OCTOBER 8, 2024

Next Post Industrial Chiller Maintenance: Key Practices, Preventive Maintenance Checklist & Sensor Monitoring Resources Explore the latest industrial maintenance best practices, trends and news from ATS and learn from industry experts and leading manufacturers.

Factory Worx

MAY 11, 2022

Read Our Blog. Why Are Digital Manufacturing Dashboards Important in Industry 4.0? Naturally, data and manufacturing dashboards are critical aspects of this process. The manufacturing analytics dashboard converts the never-ending data stream from real-time monitoring devices into simple visual displays and actionable insights.

Factory Worx

MAY 19, 2022

Read Our Blog. How does OEE Help in the Food Manufacturing Industry? Overall Equipment Effectiveness (OEE) is the go-to metric for food manufacturing facilities to recognise losses and benchmarking advancement toward improving throughput performance. It's used to figure out what percentage of manufacturing time is productive.

ATS

SEPTEMBER 5, 2023

Now, assume that the manufacturer had been keeping records of failures and decided to look at MTBF over the past 6 months. The manufacturer uses the same formula, plugging in data from the last 6 months, over which the equipment had experienced 6 failures during 1200 operational hours. Over that same time, two failures occur.

ATS

OCTOBER 15, 2024

Share Introduction to criticality analysis Manufacturers with a mandate to reduce downtime on the factory floor and improve their operational efficiency find it best to employ criticality analysis to help them prioritize maintenance tasks. They view maintenance holistically in terms of addressing risk, costs and impact on their operations.

ATS

JULY 21, 2023

Share Maintenance planning is a core component of any effective, efficient manufacturing maintenance program. Maintenance metrics: Equipment, processes and personnel should all have KPIs (key performance indicators) that can be tracked and measured in order to identify areas of need and improvement. What is maintenance planning?

MRPEasy

OCTOBER 5, 2023

Supplier performance management is a vital supply chain process for any manufacturer or distributor that sources its raw materials or other items from external vendors. Effective SPM can bring a wealth of internal benefits and help foster better supplier relationships. What is supplier performance management?

CMTC Manufacturing Tech

MAY 16, 2022

Strategic planning, budgeting, and forecasting are integral to the success of small and medium-sized manufacturers (SMMs). This spending plan will aggregate more niche financial outlines like production and manufacturing overhead budgets. Identify Key Tactics and Corresponding KPIs. Analyze Internal and External Environments.

iBASEt

SEPTEMBER 14, 2022

Complex manufacturing processes involve hundreds or even thousands of steps to make a finished product. It’s the science of analyzing data patterns to discover opportunities for optimizing manufacturing processes. Product launches are a key event for manufacturers, critical to revenue, growth, and reputation.

Infinite Uptime

JULY 6, 2022

Process manufacturers typically operate in data-rich environments and know their plants inside out. Even if this information exists within the manufacturing ecosystem, the plant maintenance and operational heads don’t really know how to use it to achieve optimum plant productivity. . appeared first on Infinite Uptime Blog.

ATS

MAY 1, 2025

These layouts, also called shops, map the route taken by products through the manufacturing process. For example, manufacturers experiencing sustained growth may experience SKU proliferation as new products are added to workflows. Consider KPIs such as lead time, machine uptime rate, and overall equipment effectiveness (OEE).

ATS

MARCH 18, 2025

Further complications arise from the use of Just-in-Time (JIT)productionand Lean manufacturing practices and the frequency with whichProductionschedules change. On top of this,Maintenance activitycan have a big impact on quality control in manufacturing. This means sharing in KPIs.

ATS

APRIL 24, 2025

Share One of the toughest challenges for manufacturers is balancing maintenance requirements with production schedules. Not to worry below, well not only break down what makes multi-facility maintenance uniquely challenging but also share practical strategies to help manufacturers streamline operations. Interested in learning more?

CMTC Manufacturing Tech

NOVEMBER 14, 2024

In this blog, we’ll outline the six steps to creating an effective strategic plan. After setting goals, ensure you measure them with specific KPIs relevant to each department. However, small and medium-sized manufacturers may not have the resources or bandwidth necessary to engage in effective strategic planning.

CMTC Manufacturing Tech

APRIL 24, 2025

This blog is the first in a three-part series introducing CMTCs approach to operational best practices through continuous improvement. Continuous improvement is the process of systematically identifying and eliminating waste within your manufacturing and administrative processes, workflows, and services.

Expert insights. Personalized for you.

We have resent the email to

Are you sure you want to cancel your subscriptions?

Let's personalize your content