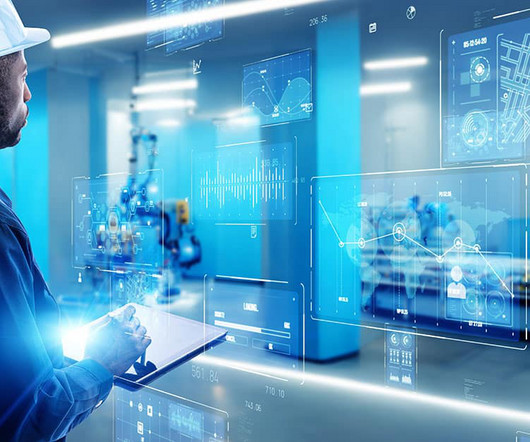

What is a CMMS (Computerized Maintenance Management System)?

ATS

JANUARY 8, 2025

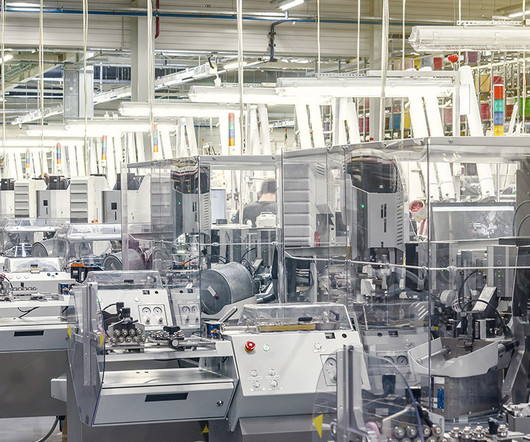

Whiteboards, cards and spreadsheets may have had their place, but manufacturers who are serious about improving their competitive position should look to one tool, a computerized maintenance management system (CMMS). This blog takes a close look at CMMS software. This is only part of what the modern CMMS does.

Let's personalize your content