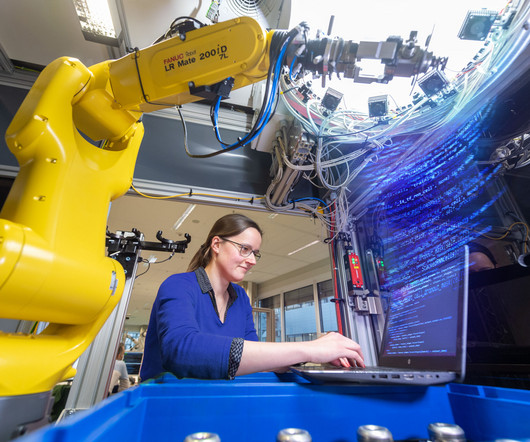

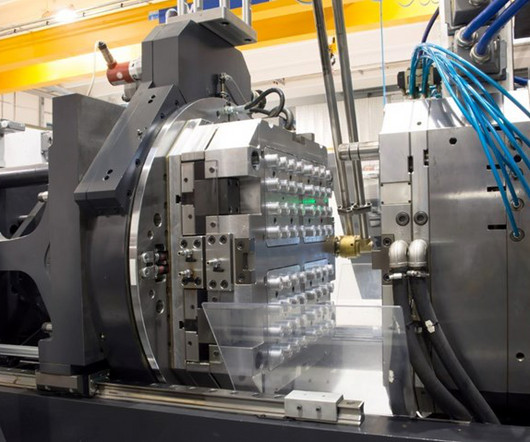

Bosch implements generative AI in manufacturing to improve efficiencies

Automation Mag

DECEMBER 7, 2023

As a manufacturing company, established factory outfitter, and Industry 4.0 trendsetter, Bosch aims to play a leading role in the development and application of industrial AI,” Hartung says. AI has excellent potential for innovation and can make human work even more productive.

Let's personalize your content