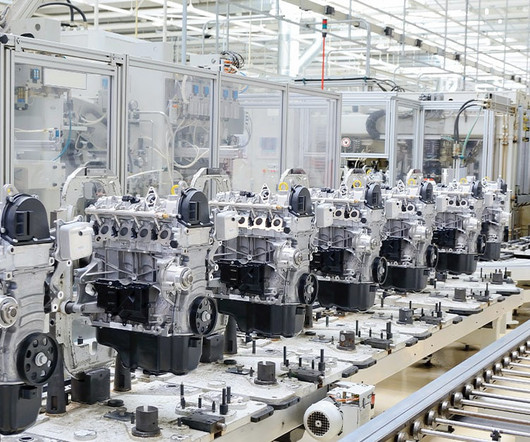

Capping and Filling Machine Maintenance

ATS

APRIL 10, 2025

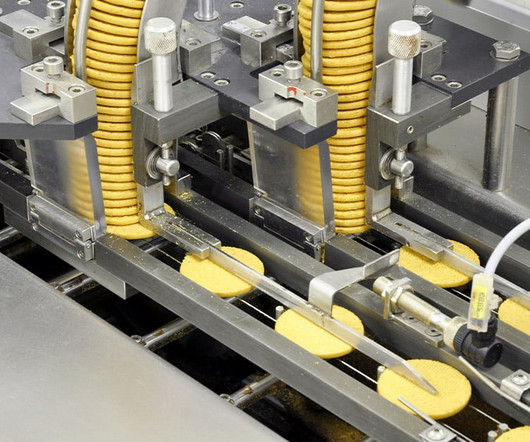

Share Capping andfilling machinesare critical in packaging and production lines for many industries. They help optimize product integrity, speed, and consistent packaging results across sectors such as food and beverage, pharmaceuticals, and consumer goods. Worn seals and gaskets: They can lead to leaks or incorrect fill volumes.

Let's personalize your content