Spatial Computing, AI Meet the Machine Shop

Modern Machine Shop

APRIL 23, 2024

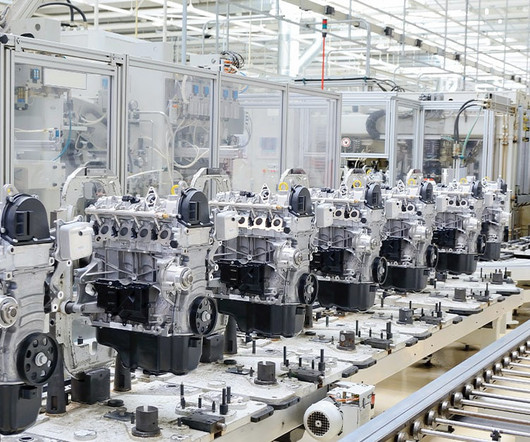

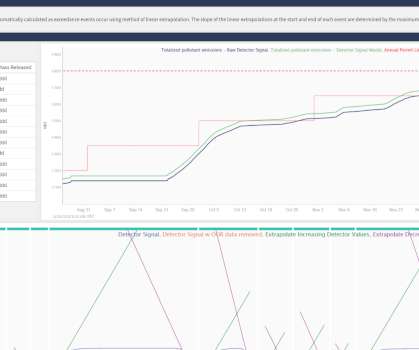

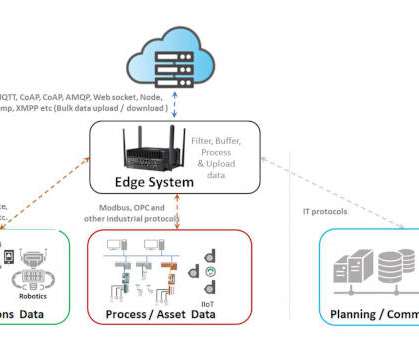

In the past, when a service technician came to our facilities, they came with few diagnostic tools, hand tools and a cell phone. The spatial computer will allow the machinist to actively monitor the equipment in real time, including the control and the inside of the machines, while they are working. Let that sink in!

Let's personalize your content