Alienation from Our Work

Gary Mintchell

DECEMBER 2, 2024

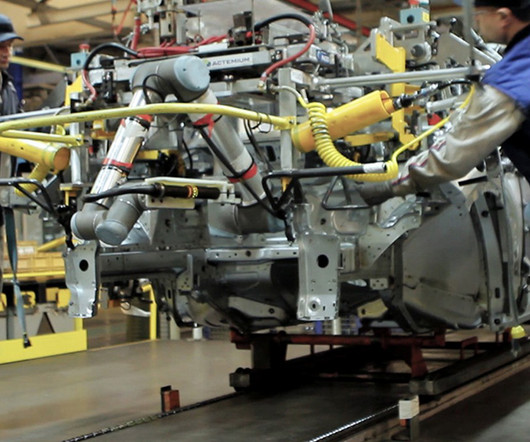

As factories multiplied and grew, most of humanity was no longer involved in this combination of skill and creativity in the production of something useful or beautiful for someone else. Karl Marx observed workers at the beginning of the Industrial Revolution in the early 1800s. He theorized something he called alienation.

Let's personalize your content