AI, Software Defined, Data Highlight Automation Fair

Gary Mintchell

NOVEMBER 26, 2024

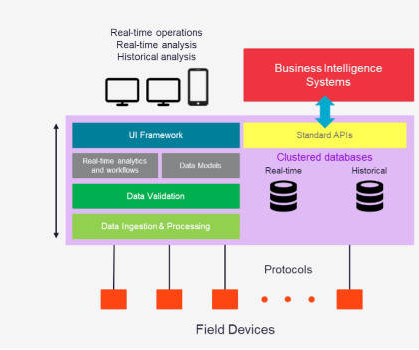

Blake Moret deserves credit for many reasons during his tenure as CEO of Rockwell Automation. Rockwell gained some benefit, but in the end the benefits were less than spectacular. These comments introduce the 2024 edition of Automation Fair. Rockwell has enhanced the edge-to-cloud experience.

Let's personalize your content