FieldComm Group Announces 2023 Plant of the Year

Gary Mintchell

JANUARY 23, 2024

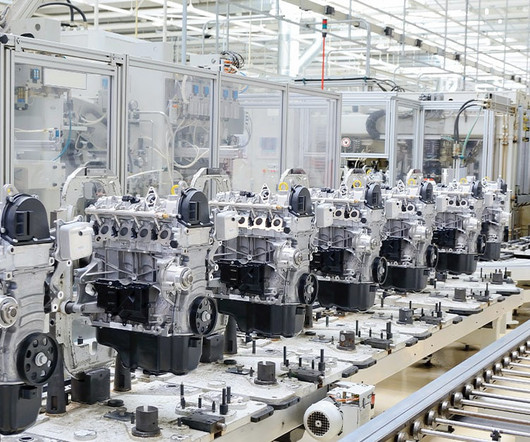

Plant in Kashima, Japan, has been selected the 2023 Plant of the Year. This is the 21st annual awarding of this unique international honor, presented to end user companies in the process automation industry to recognize the exceptional and valuable application of FOUNDATION Fieldbus, FDI and/or HART Communication technologies.

Let's personalize your content