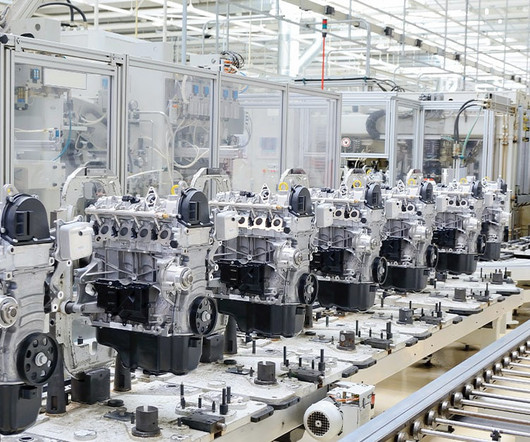

Machine Downtime in Manufacturing

ATS

MAY 14, 2024

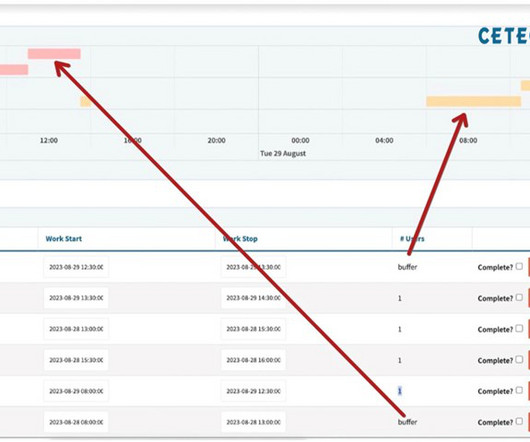

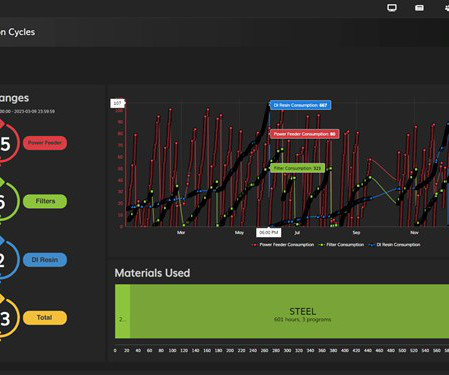

That can mean it takes longer to get an order out, that overtime work is needed to stay on schedule, or a combination of the two. Downtime splits into two types: Planned downtime: This is where time is made available in the production schedule for tasks such as machine inspections and maintenance. It’s always disruptive.

Let's personalize your content