Industrial Boiler Maintenance: Essential Tips and Checklist

ATS

NOVEMBER 4, 2024

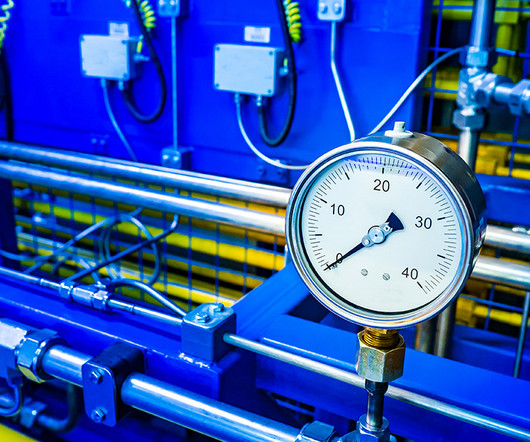

This refers to instrumenting the boiler and related equipment — such as the fuel system, — with sensors that provide information on status and condition. It’s even possible to perform corrosion monitoring , using ultrasonic sensors that measure and report tube thickness. This sensor should be checked regularly.

Let's personalize your content