Gears of Progress: Inside the Dynamic Machine Manufacturing Ecosystem

Frost & Sullivan Manufacturing

DECEMBER 23, 2024

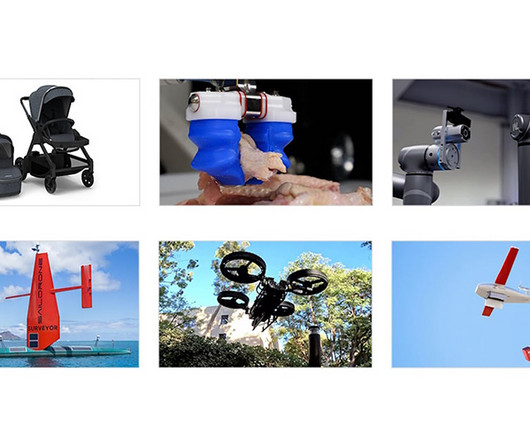

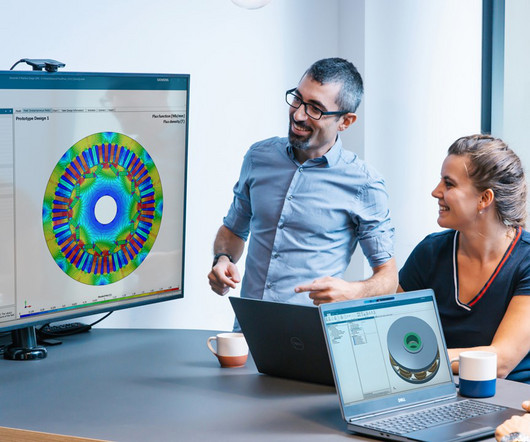

At the heart of this transformation lies software-defined automation , enabling the seamless integration of machines, processes, and data to achieve real-time adaptability. Are you refining your growth strategy based on the latest disruptions in the Machinery industry? technologies with agility and focus.

Let's personalize your content