How open process automation will shape the future of pump control

Control Engineering

MAY 3, 2023

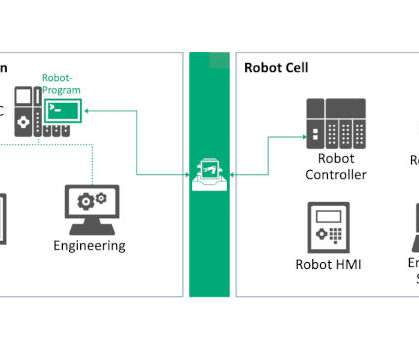

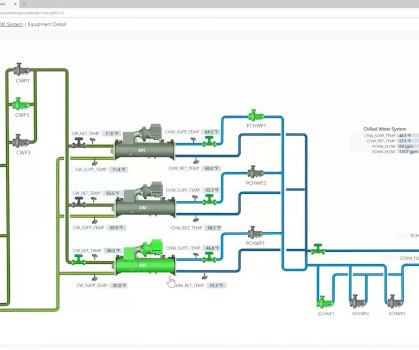

On the other are general-purpose devices, such as programmable logic controllers (PLCs), which are programmed to control multi-pump systems along with peripheral functions, or even entire pump stations. It would be built on an open platform that supports application development in a variety of programming environments from different sources.

Let's personalize your content