IMTS / Hannover Messe Chicago Recap

Gary Mintchell

SEPTEMBER 22, 2022

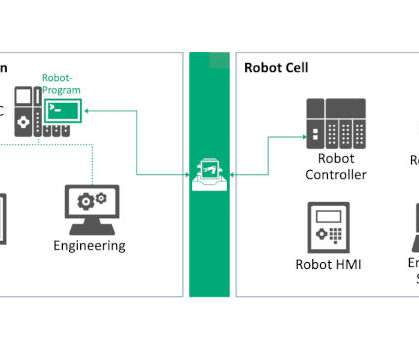

D:PLOY automatically discovers and configures all the components in a robotic cell – including any leading collaborative or light industrial robot arm and tools – while also integrating external I/O from sensors and machines. D:PLOY will be available for all common robotic applications, making deployment up to 80% faster.

Let's personalize your content