PICMG InterEdge and OPAF Partnership to Advance Open Process Control Technology

Gary Mintchell

MAY 6, 2024

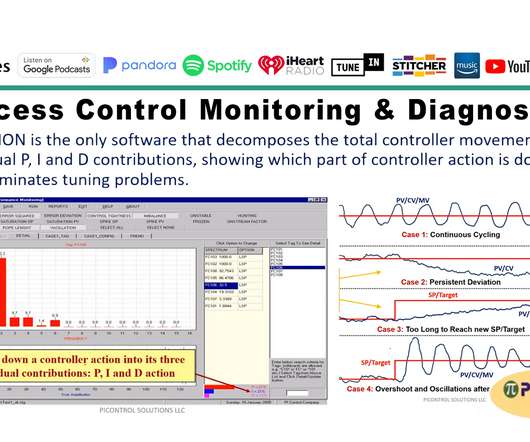

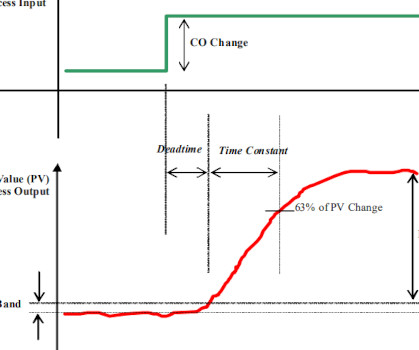

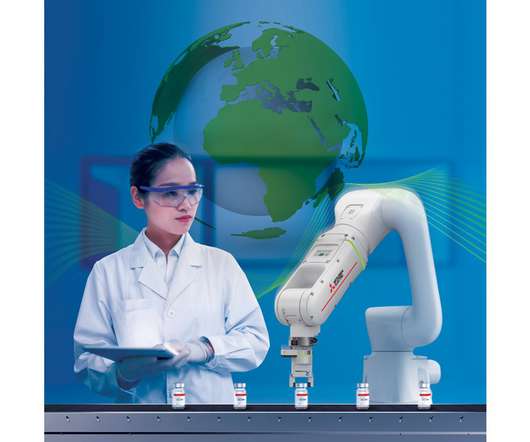

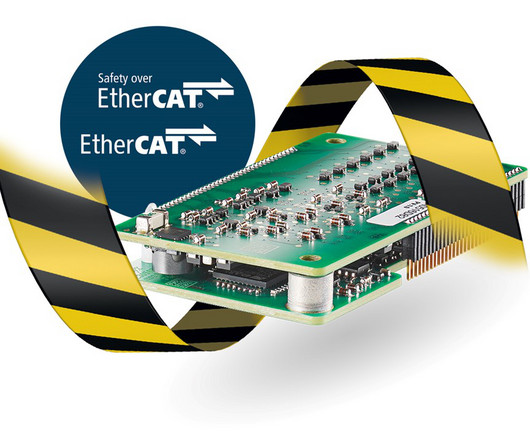

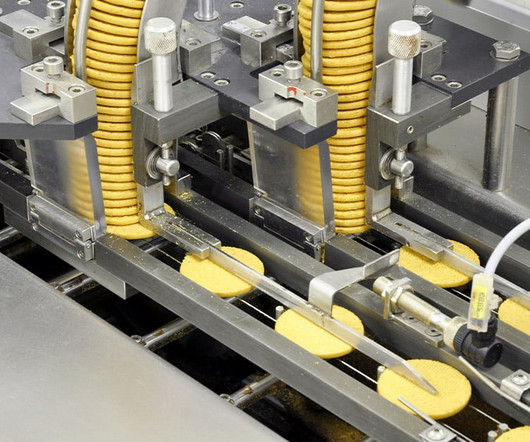

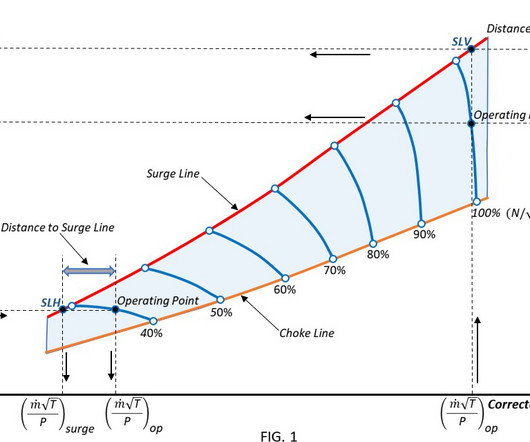

The InterEdge specification introduces a modular open architecture that delivers state-of-the-art I/O abstraction and flexibility and in a common physical form factor. It supports the OPAF and O-PAS goals of reducing integration, maintenance, and upgrade costs in the highly fragmented and largely proprietary process control technology market.

Let's personalize your content