Realtime Robotics appoints Ville Lehtonen vice president of product

Robotics Business Review

DECEMBER 1, 2024

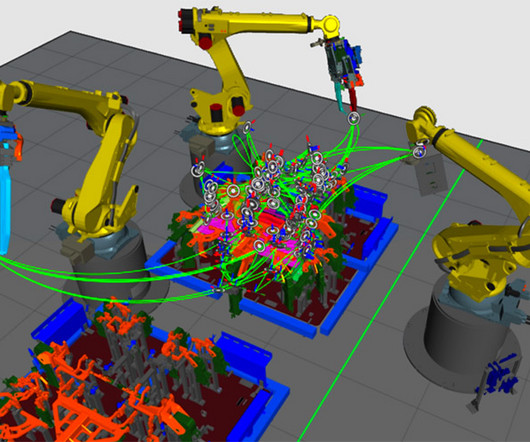

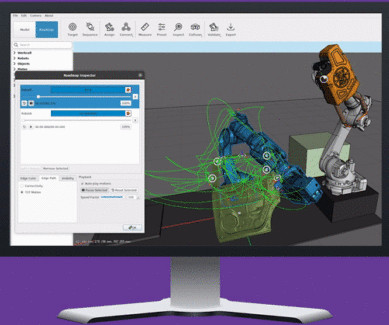

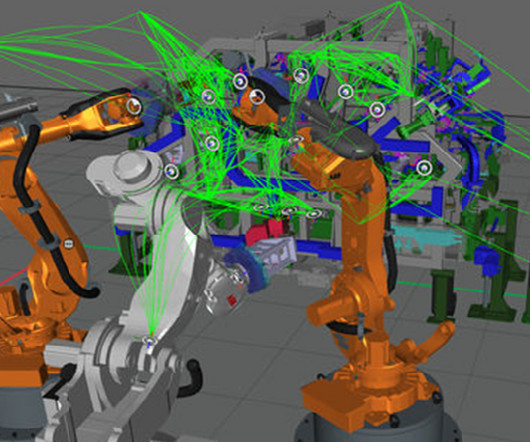

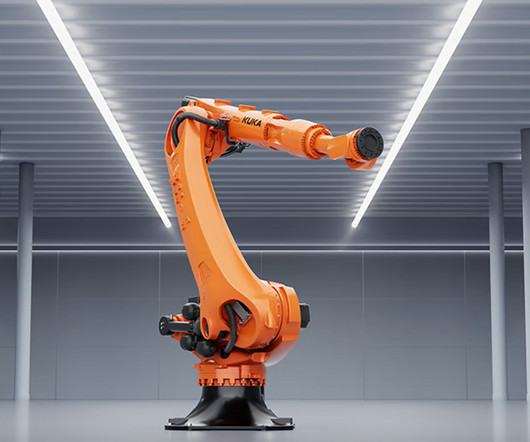

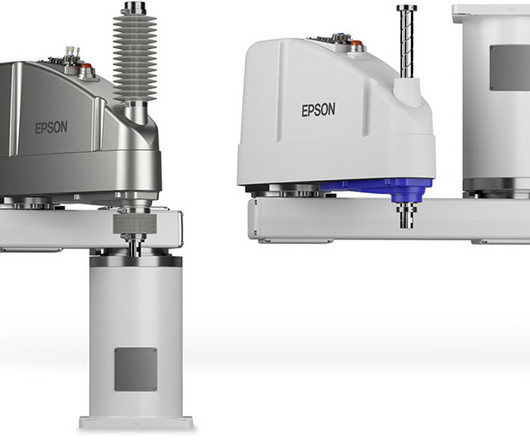

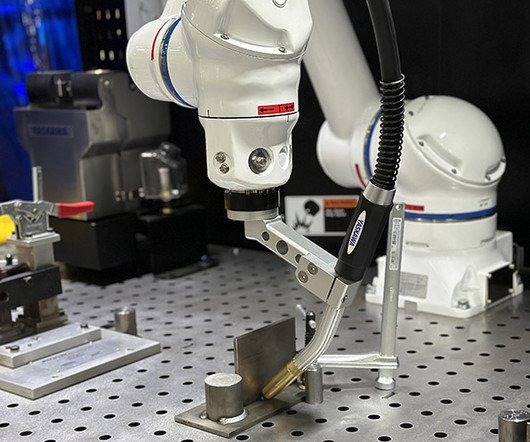

Optimization evaluates multiple paths, sequences, poses, end-of-arm tool rotations, and interlocks for robots within a workcell. Source: Realtime Robotics. Realtime Robotics, a leader in collision-free autonomous motion planning for industrial robots, last week named industry veteran Ville Lehtonen as its vice president of product.

Let's personalize your content