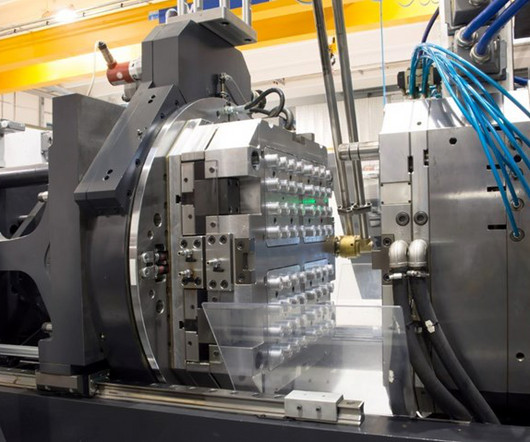

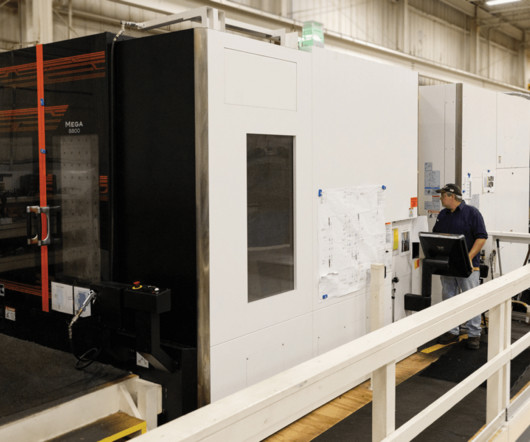

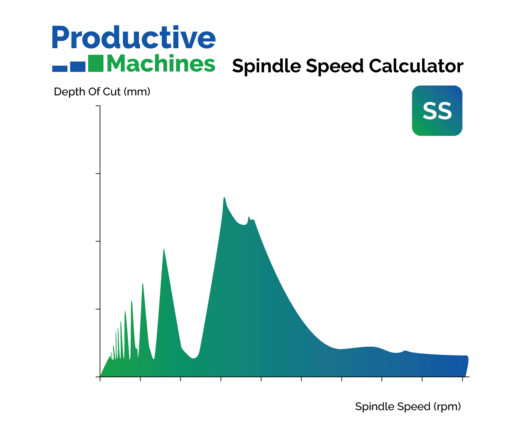

Automated Toolmaking System for Reducing Lead Times and Cost

Mold Making Technology

MAY 12, 2025

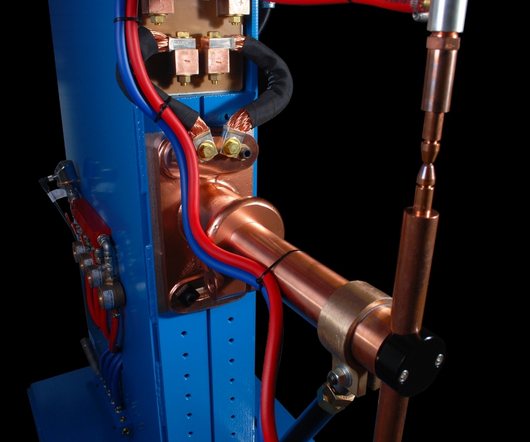

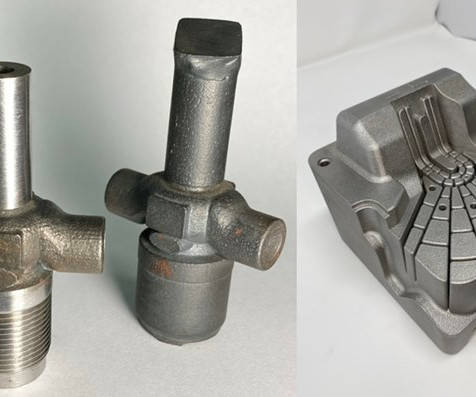

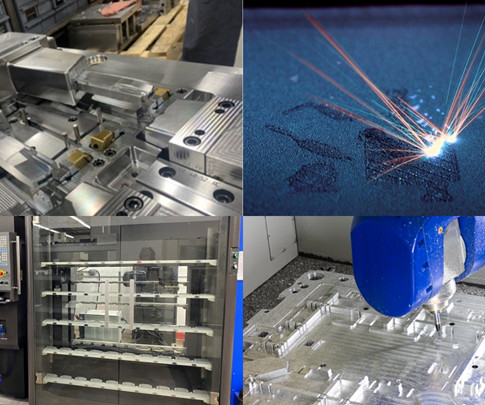

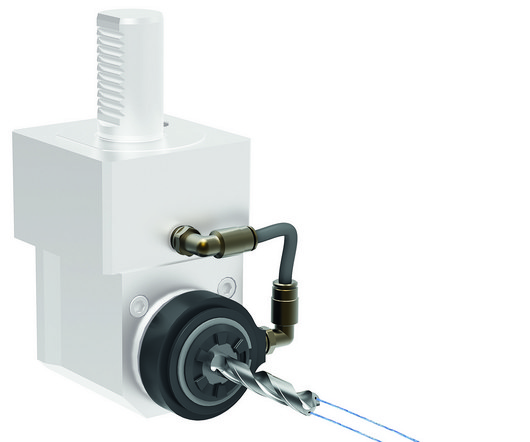

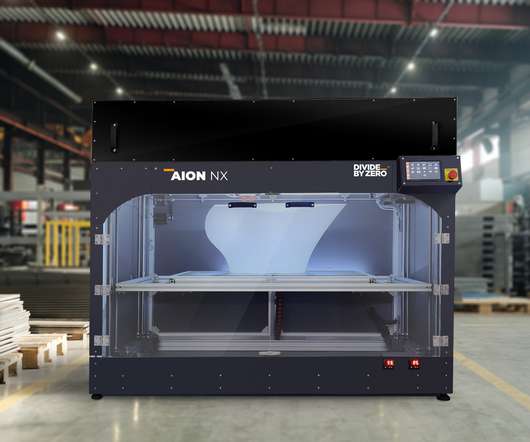

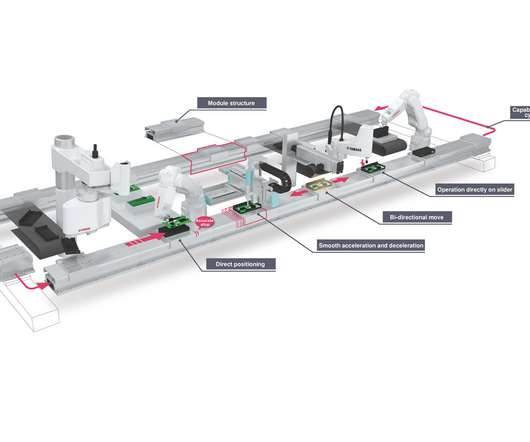

This integrated approach was developed for injection mold tooling and is said to significantly reduce lead times, costs and labor to empower moldmakers with even more efficiency and precision. Also, integrating conformal cooling channels enhances thermal management, reduces cycle times and improves part quality.

Let's personalize your content