Video interview: Benefits and applications for SPE and Ethernet-APL

Control Engineering

APRIL 13, 2023

However, with these issues solved, Ethernet has increasingly become the preferred industrial network, particularly in discrete manufacturing.

Control Engineering

APRIL 13, 2023

However, with these issues solved, Ethernet has increasingly become the preferred industrial network, particularly in discrete manufacturing.

Control Engineering

AUGUST 3, 2023

Driving advanced data sharing for demanding manufacturing cycle times To accommodate increasingly demanding cycle times while offering exacting performance and maximum uptime, engineers should look for drives and controls that use a network technology that ensures determinism.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Control Engineering

AUGUST 12, 2022

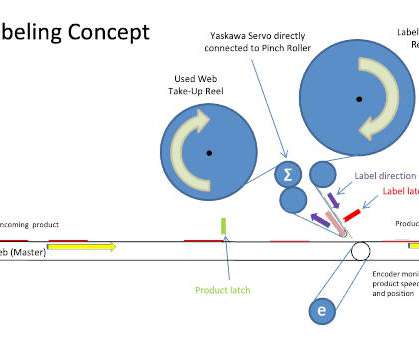

A function block called a labeler keeps track of four types of data: Product, label, label camera and camera control. To speed up the development process, an IEC 61131-3 function block called “labeler” is something users can incorporate into the coding process that improves the ease of use. Learning Objectives. Courtesy: Yaskawa.

Control Engineering

FEBRUARY 8, 2023

There’s no need for clock synchronous application operation, because it’s a very simple application.The cycle times, ver roughly, are tens of millisecond. This also is not synchronized via a clock because it’s single axis and maybe not required, but the cycle times are a little more stringent.

Fabricating & Metal Work

APRIL 22, 2024

AI-enabled mobile robots can transform sectors like discrete manufacturing, logistics and laboratories,” Segura said. When cycle times require high-speed travel, front and rear-mounted laser scanners ensure safe operation in all travel directions. The required safety functions are complex. m above the ground.

Control Engineering

OCTOBER 5, 2022

Advances in machine tool hardware, software, subtractive and additive manufacturing processes and related system integration were among four major Siemens IMTS announcements. New technology functions for the Siemens Sinumerik One computer numerical control (CNC) simplify operation and increase productivity. Courtesy: Mark T.

Control Engineering

AUGUST 28, 2023

AP backplane communications brings together enormous functionality and creates a higher level of integration among our devices than we’ve ever had.” The AP ecosystem makes it efficient for end-user customers to add functionality as needs arise. Users input key parameters, such as mass, stroke/travel distance and cycle time.

Let's personalize your content