Yokogawa Updates OpreX Process Automation Family

Gary Mintchell

APRIL 10, 2024

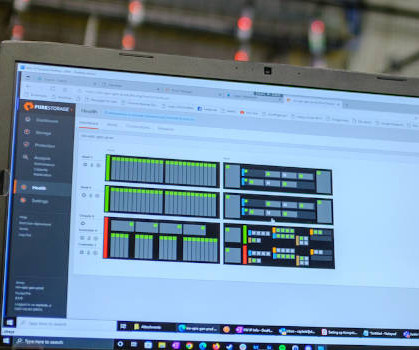

The second concerns strengthened industrial network support in CENTUM in the Control and Safety System family of solutions. Connection with other systems This product was developed with the ability to link to Yokogawa’s OpreX Collaborative Information Server. OpreX Robot Management Core Yokogawa Electric Corp.

Let's personalize your content