Generative AI Industrial Copilots to Deliver Contextual Intelligence

Gary Mintchell

DECEMBER 14, 2023

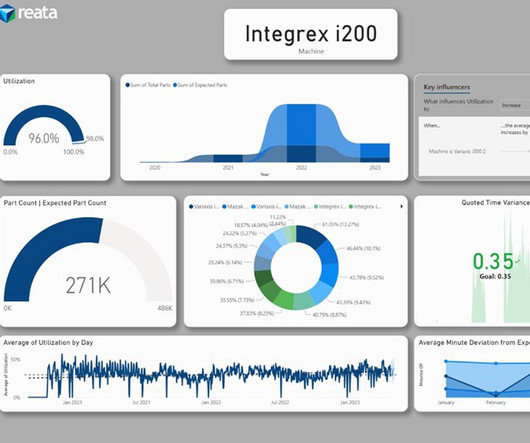

The copilots leverage Microsoft Azure OpenAI alongside an industrial knowledge graph that includes events, sensor data, asset details, product documentation and manuals, and reliability and maintenance reports. All three copilots contextualize, process, and analyze data from various manufacturing sources.

Let's personalize your content