Machine Uptime and Availability for Manufacturing

ATS

MAY 14, 2024

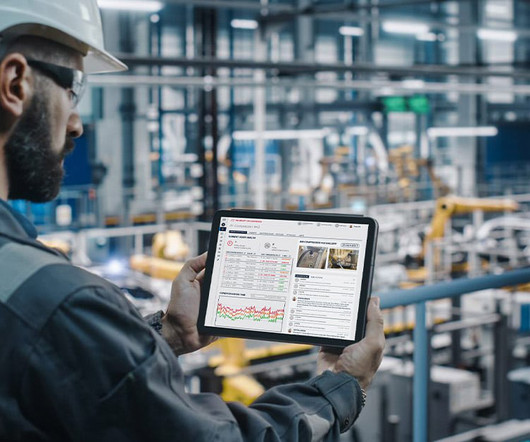

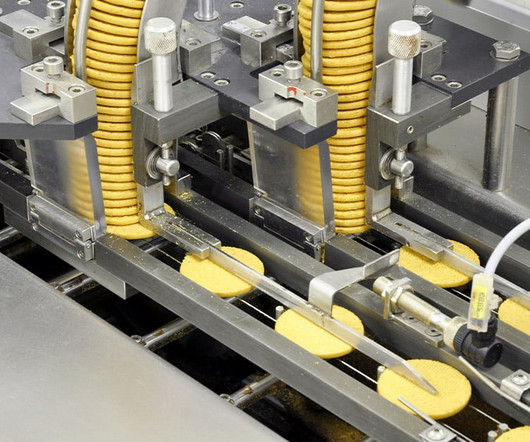

High levels of machine uptime indicate high productivity and efficiency. Just because a machine or line is available, it doesn’t mean that it’s running or “up.” This blog was written to help manufacturers identify opportunities to improve machinery uptime. What is machine uptime?

Let's personalize your content