Design Failure Mode Effects Analysis (DFMEA)

ATS

FEBRUARY 29, 2024

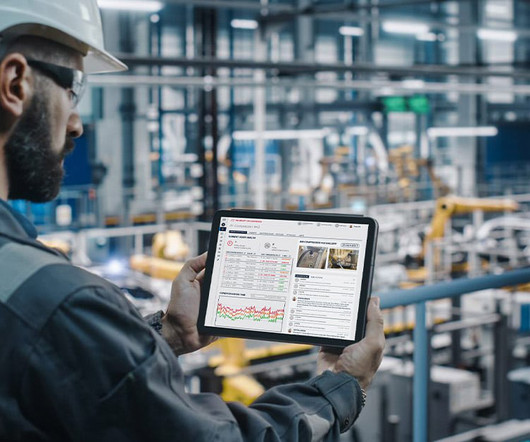

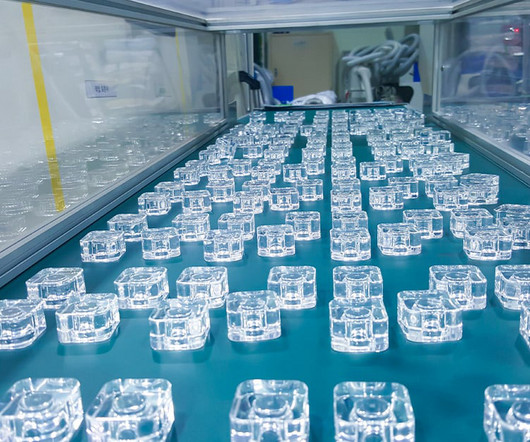

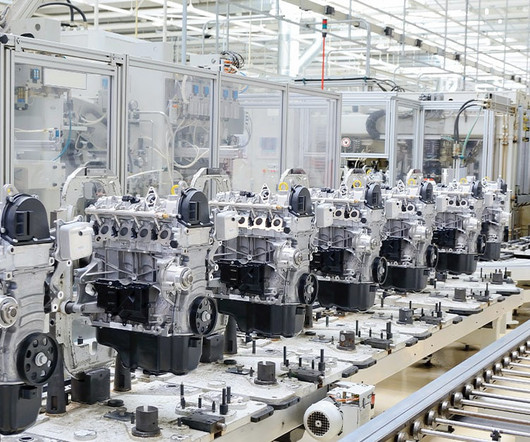

This is the principle behind failure mode and effects analysis (FMEA), a structured approach to identifying what could go wrong and prioritizing which should be addressed first. Design failure mode and effects analysis (DFMEA) is a form of FMEA tailored to the product design process. What is DFMEA?

Let's personalize your content