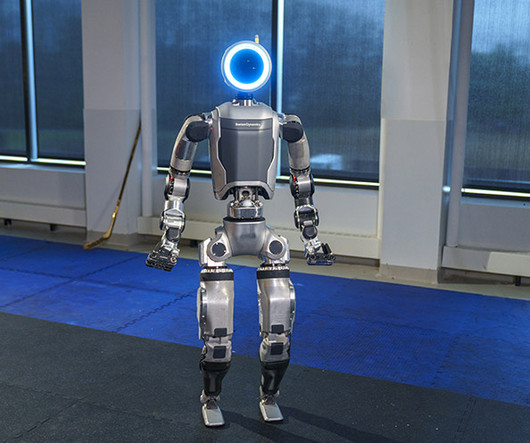

How Agility Robotics crosses the Sim2Real gap with NVIDIA Isaac Lab

Robotics Business Review

NOVEMBER 8, 2024

We use cost functions to judge whether a command achieves a more or less useful response Over the course of significant simulation time — but only hours in real time — we learn a control policy that will achieve the goals we want, like walk around without falling, even if there’s an unexpected pothole in the ground.

Let's personalize your content