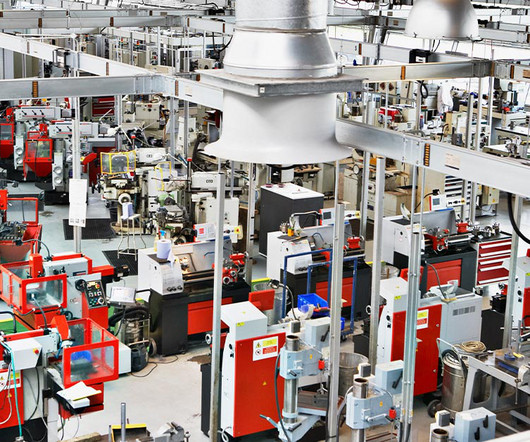

The Key Role of Industry 4.0 Technologies in Process Optimization

Plataine

NOVEMBER 14, 2022

In order to achieve this goal, they must examine each step of their current workflow and form dedicated optimization strategies. The post The Key Role of Industry 4.0 Manufacturers in every field are always busy looking for ways to improve their business operations and scale up their throughput - it’s an endless challenge.

Let's personalize your content