Do More with Ultramodern Machines

Fabricating & Metal Work

APRIL 22, 2025

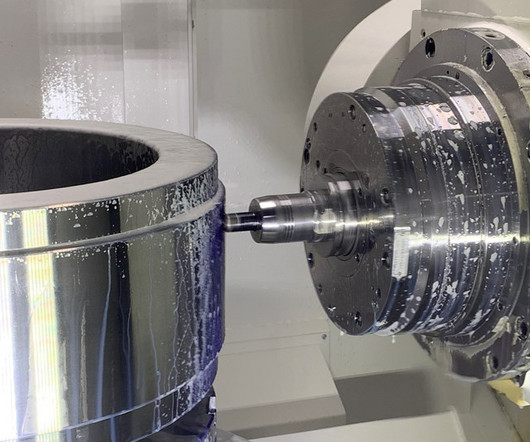

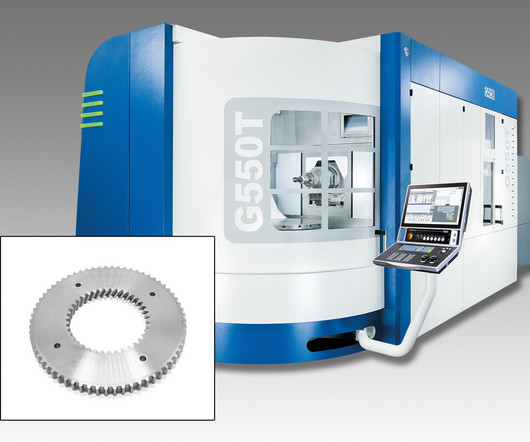

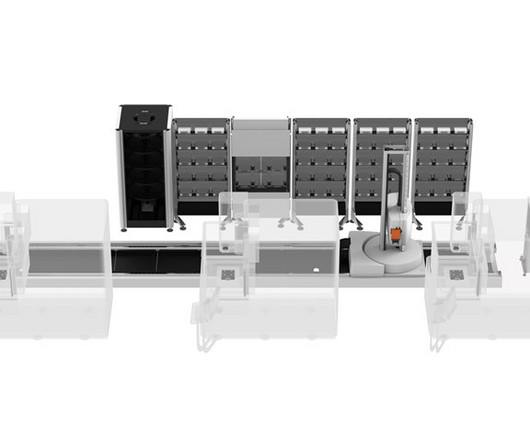

At the heart of this transformation is ultra-precision machining, powered by advanced CNC systems, robotic automation, and artificial intelligence. The landscape of the metal cutting industry is being altered by ultramodern machining. Multi-axis machining expands these capabilities, facilitating intricate shaping and contouring.

Let's personalize your content