The Link Between CNC Process Control and Powertrain Warranties

Modern Machine Shop

JULY 30, 2023

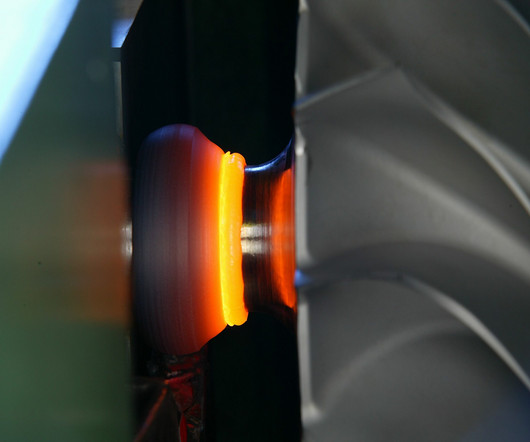

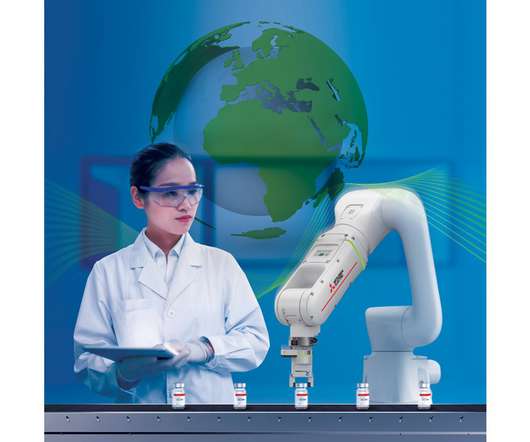

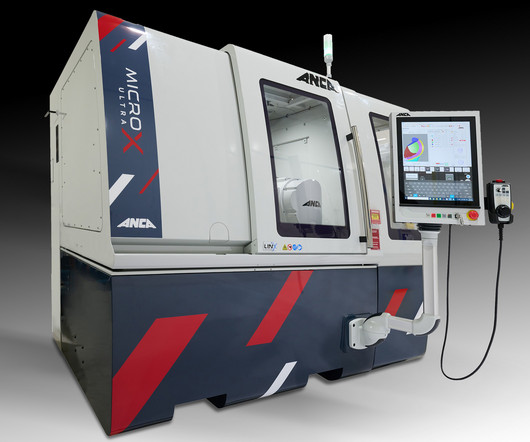

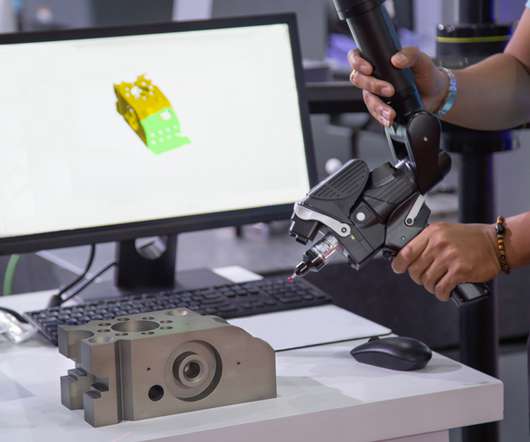

What has changed between then and now, of course, is that automotive manufacturers have achieved higher levels of accuracy in their design and manufacturing. Using its own Intelligent Process Control (IPC) software, the system can detect the presence of tool wear and send tool offsets to the machine tool CNC in real time.

Let's personalize your content