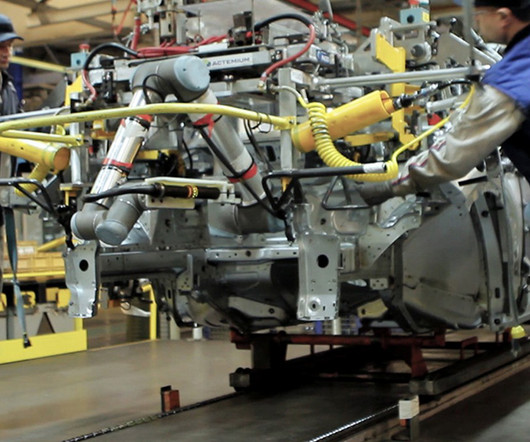

Massimo Motor adds mobile robots to production line for UTVs

Robotics Business Review

DECEMBER 26, 2024

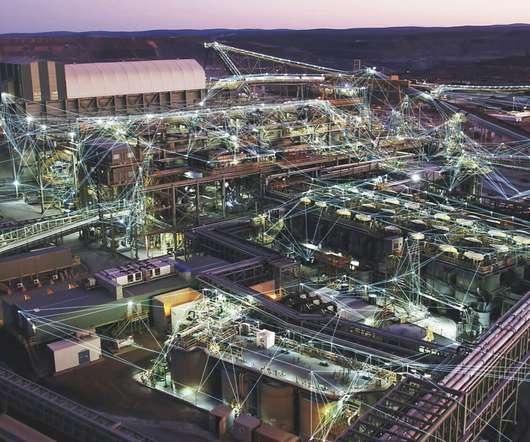

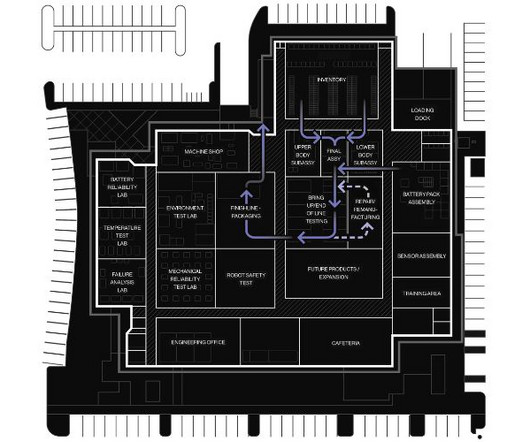

Massimo Motor’s new production facility with automated guided robots in Garland, Texas. Source: Massimo Group Massimo Motor Sports LLC, a manufacturer and distributor of powersports vehicles and pontoon boats, has added robotics to its new assembly line to streamline production and enhance quality control.

Let's personalize your content