Pickle Robot gets orders for over 30 unloading systems plus $50M in funding

Robotics Business Review

NOVEMBER 21, 2024

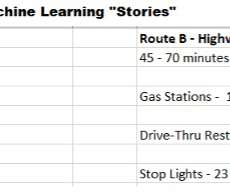

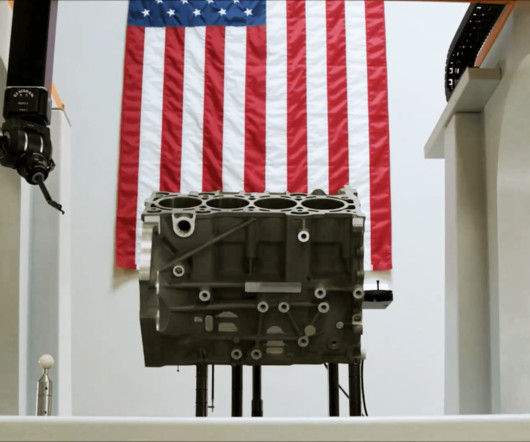

Source: Pickle Robot Robotic truck unloading fits the classic definition of dull, dirty, or dangerous jobs worth automating. The company claimed that its Physical AI combines sensors and a computer vision system with industrial robotics, machine learning, and artificial intelligence. Pickle Robot Co.

Let's personalize your content