Top Trends in 2025

Automation Mag

APRIL 15, 2025

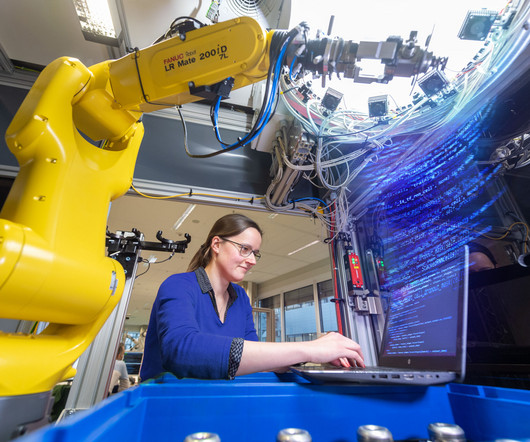

However, industry experts suggest that automation and advanced manufacturing technologies might offer support against constantly changing economic forces and global market conditions. That said, we as manufacturers have to become smarter, faster, and bolder.

Let's personalize your content