The Shift Toward Smarter Shops: Real-World Stories of Data-Driven Manufacturing

Modern Machine Shop

APRIL 29, 2025

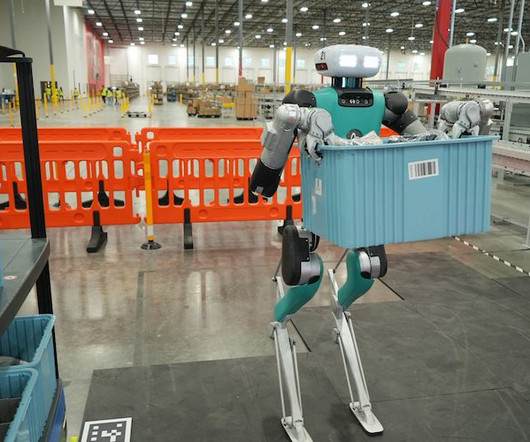

inches per minute and are already in use at the company’s Pfronten, Germany facility — we are clearly moving toward a collective vision of fully-automated production. Digital twins and simulation are growing increasingly sophisticated. Like the steady pace of these AGVs — which travel approximately 1.77

Let's personalize your content