How to optimize industrial motor communications, Part 3, smart manufacturing

Control Engineering

FEBRUARY 15, 2023

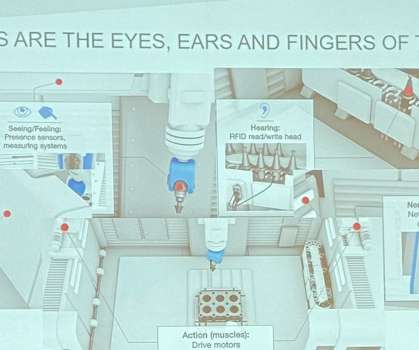

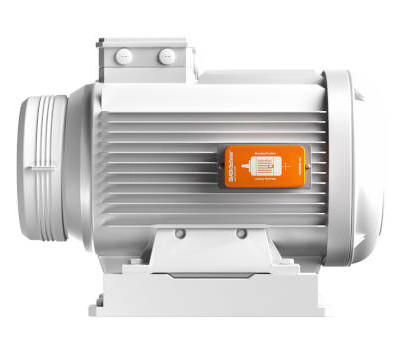

Learning Objectives Understand how motor-drive communications help enable smart manufacturing. Motor communication insights Motor-drive communications using industrial Ethernet protocols can help enable smart manufacturing. In smart manufacturing, digital twins predict operations we expect.

Let's personalize your content