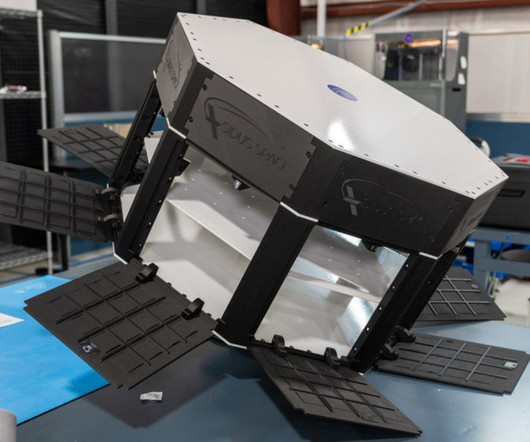

Vertiia: Australian aerospace vertical takes-off

Manufacturer's Monthly

APRIL 23, 2025

Images: AMSL Aero Discovering an application for such an innovation The story behind this innovative piece of Australian aerospace starts with Moore, who had an interest in the technology. Hanwha is a global giant when it comes to manufacturing and aerospace. We have both an engineering workforce and a technician workforce.

Let's personalize your content