Five-Axis CAM Strategies Cut Cycle Time for Two Shops

Modern Machine Shop

MARCH 4, 2025

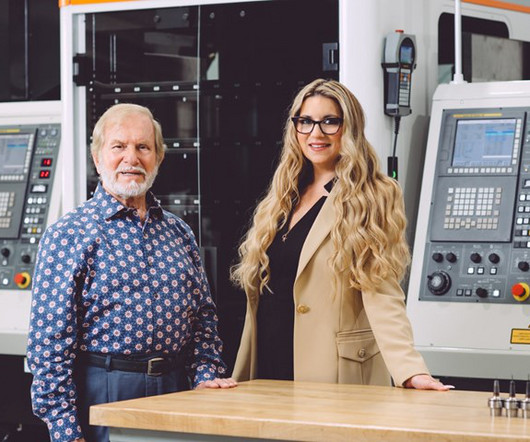

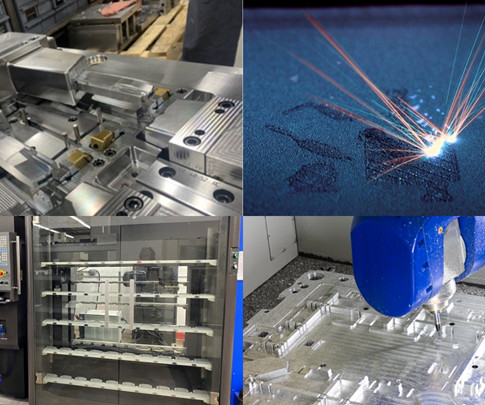

MMG (formerly named NSA Industries) is a leading manufacturer partner to OEMs and product manufacturers, offering a full suite of in-house metal manufacturing and value-added capabilities across a range of markets including semiconductors, medical, robotics, aerospace and defense. “Demand continues to go through the roof.”

Let's personalize your content