Agentic AI, SaaS, Community—The Aras Community Gathering

Gary Mintchell

APRIL 18, 2025

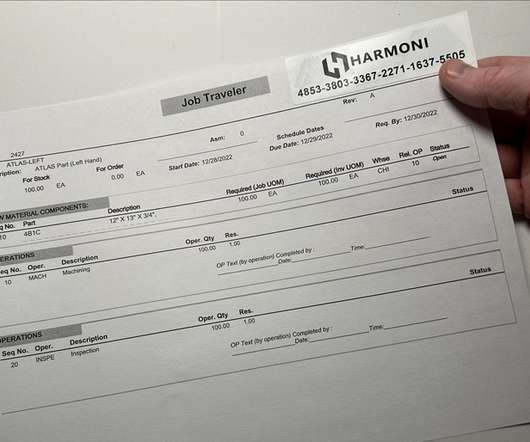

They have instances of development times cut from 3 years to 6 months. Engineers find the digital thread from PLM as a tool for collaboration. Using Aras PLM, they have realized better speed to market finding product data via natural language query. Another customer presentation came from Denso. Inconsistent data hurts the business.

Let's personalize your content