3D Scanning Quickly Solves Tool Repair Problems

Mold Making Technology

NOVEMBER 19, 2023

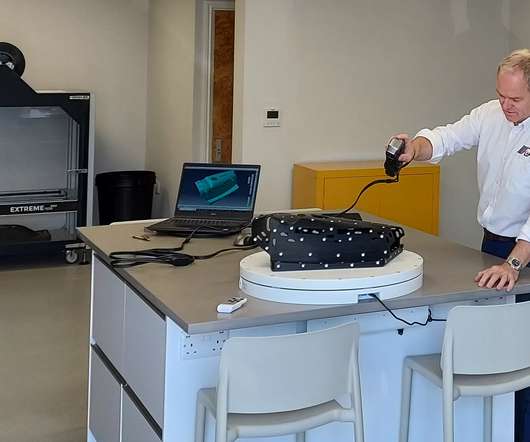

Cavity block of a hose connector set up on the 3D scanner’s stage. For example, the team successfully used various 2D vision and light-based measurement systems but then decided it was time to acquire 3D scanning technology in-house. Solution: Purchased Keyence VL-500 3D scanner to analyze the mold and measure the cavities.

Let's personalize your content