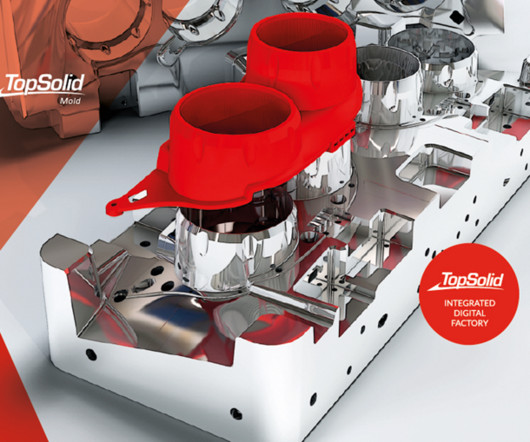

Exploring Strategies and Technologies Driving Growth, Efficiency and Sustainability in Moldmaking

Mold Making Technology

FEBRUARY 23, 2025

Isaac Trevino, MMT EAB member and business development manager for Best Tool and Engineering (BTE) shares his top article picks. Isaac Trevino is the business development manager at Best Tool and Engineering (BTE) , which was founded in 1991 and is located in Clinton Township, Michigan.

Let's personalize your content