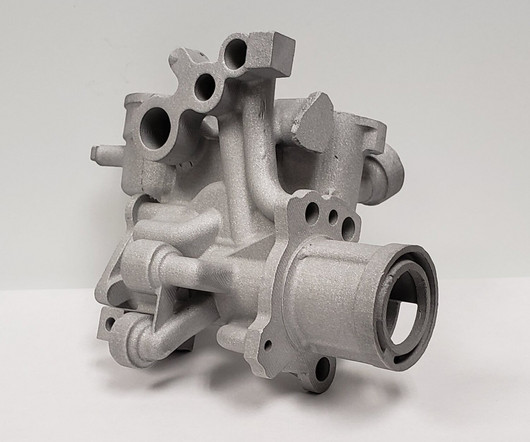

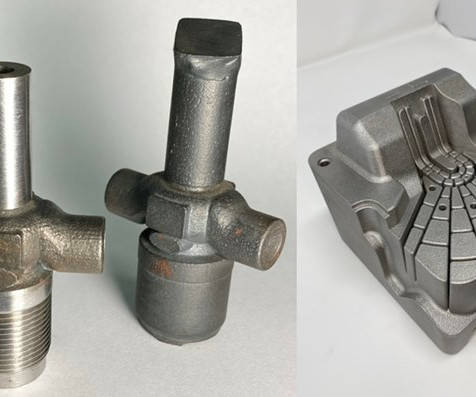

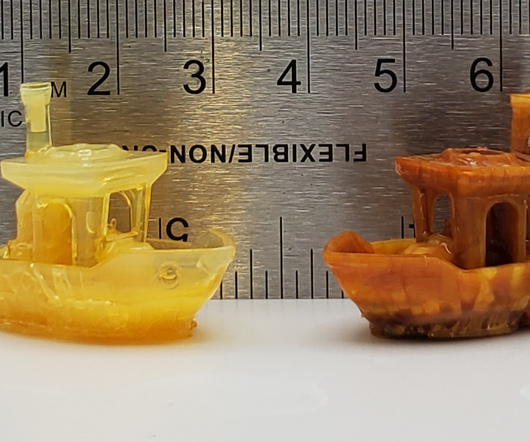

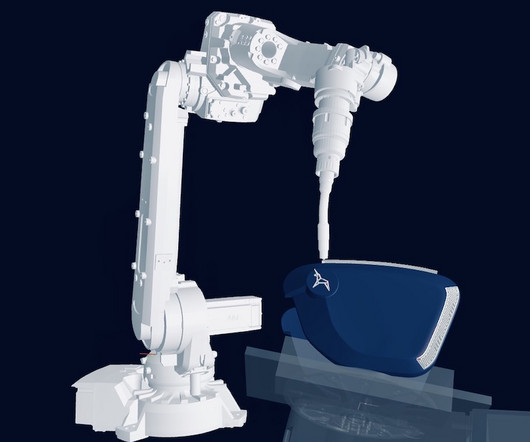

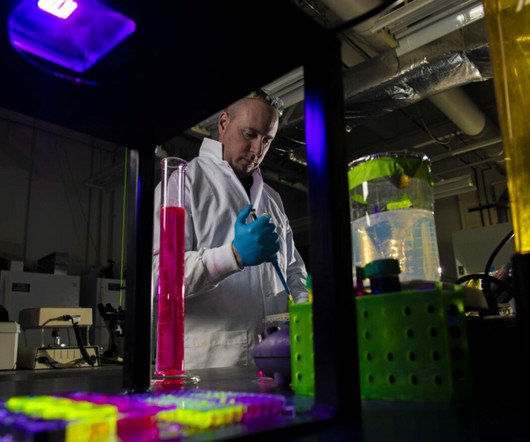

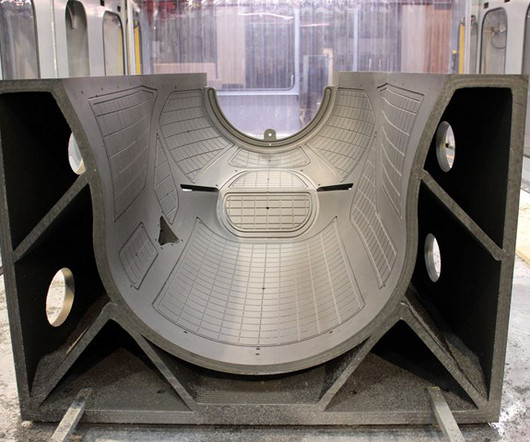

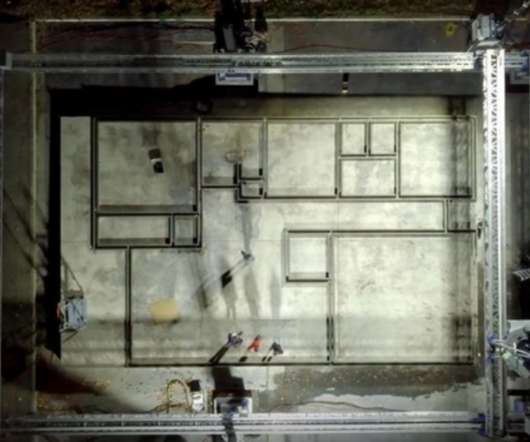

3D printing makes complex parts possible

Design World

MARCH 6, 2023

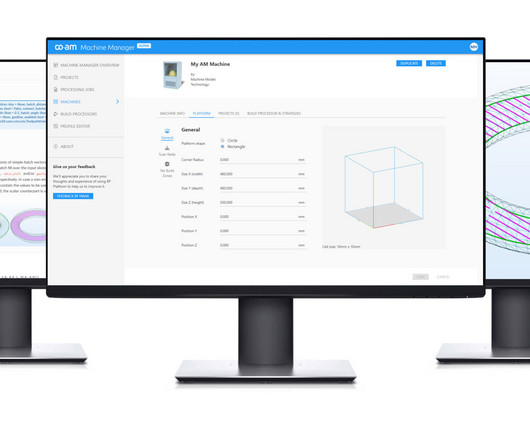

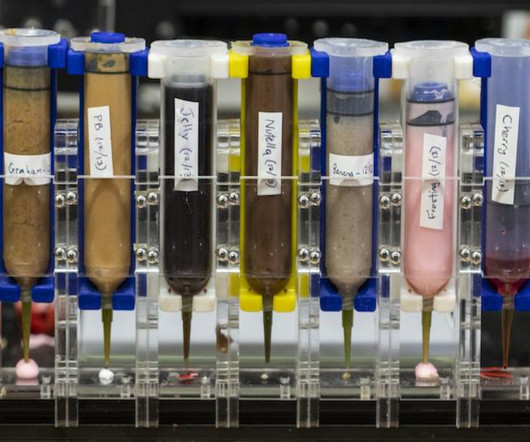

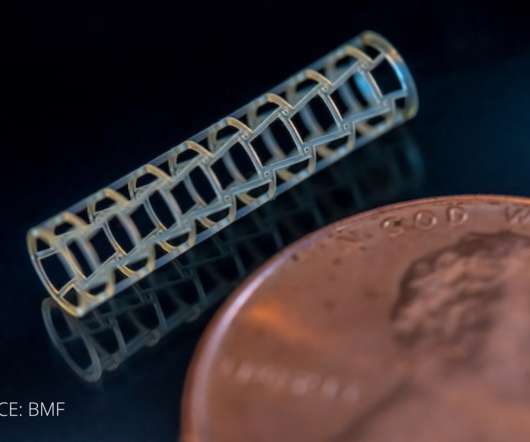

This challenging, costly, and time-consuming process requires additional steps and tooling to create soluble or ceramic cores that form complex internal ports, passages, channels, and baffles. However, manufacturers now use […] The post 3D printing makes complex parts possible appeared first on Design World.

Let's personalize your content