A 3D Printing Retrospective

Mold Making Technology

APRIL 13, 2023

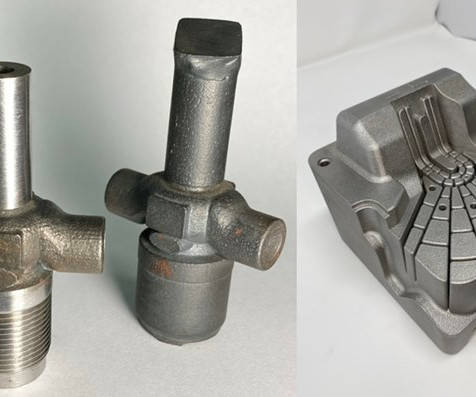

3D printing advancements and applications have gone from conformally cooled hot runner nozzles using a 3D-printed pattern to cast the part with integrated cooling circuits (left) to large DMLS 3D-printed parts in 420 stainless steel with integrated conformal cooling and InnoVent Technology for venting (right).

Let's personalize your content