3D printing with limitless design

Manufacturer's Monthly

AUGUST 9, 2022

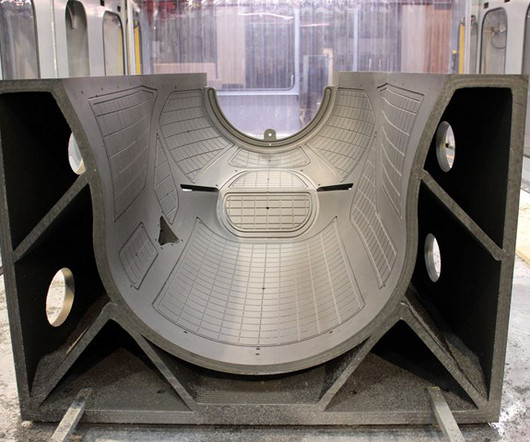

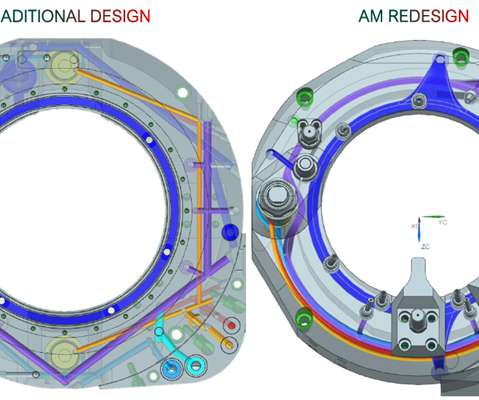

Today, VSF can print large components made of concrete as well as thermoplastic composites. An example of CNC Design’s 3D printers capability is used in aerospace applications including the manufacture of vacuum molds using high-temperature thermoplastics (PEEK) combined with carbon fibre while considerably reducing tooling costs.

Let's personalize your content