Path Robotics raises $100M to automate welding

Robotics Business Review

OCTOBER 28, 2024

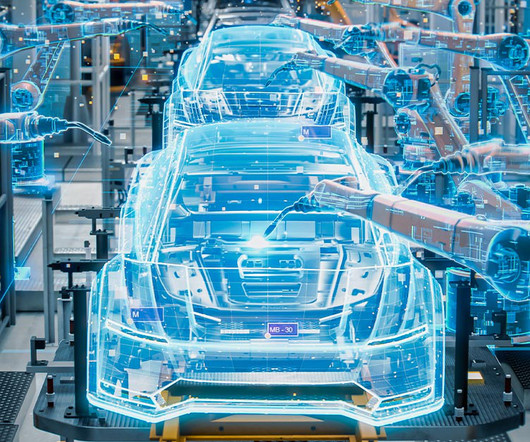

Path Robotics offers is autonomous welding robots with a RaaS pricing model. Source: Path Robotics Over the past 12 months, Path Robotics has closed $100 million in new investments. Founded in 2018 by brothers Andy and Alex Lonsberry, Path Robotics’ stated goal is to fill gaps in the manufacturing industry.

Let's personalize your content