ERP Empowers Mold Builder to Increase Speed, Efficiency, Accuracy

Mold Making Technology

APRIL 18, 2024

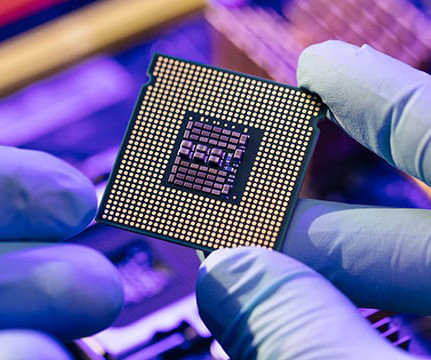

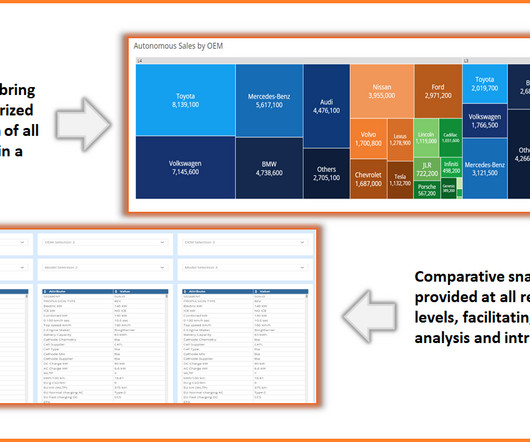

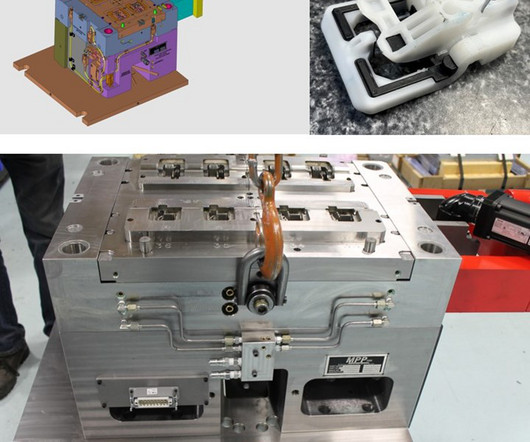

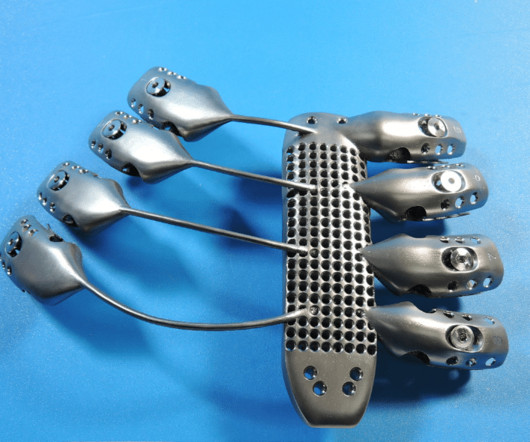

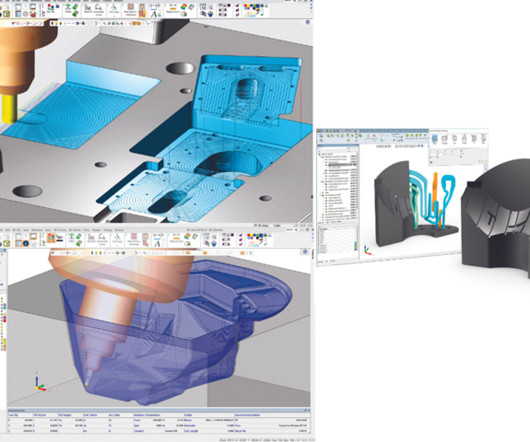

The company is ISO 9001:2015 certified, has three offshore partnerships to handle overflow work and is the largest moldmaker in the southeast U.S. began life in 1989 as a special IT project at a Detroit automotive supplier. A 46-year-old moldmaker and custom injection molder, Delta Mold Inc., Source | Delta Mold Inc.

Let's personalize your content